Chain conveyor

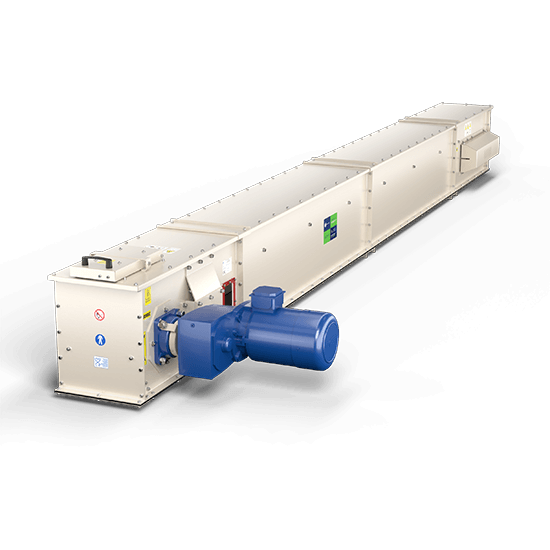

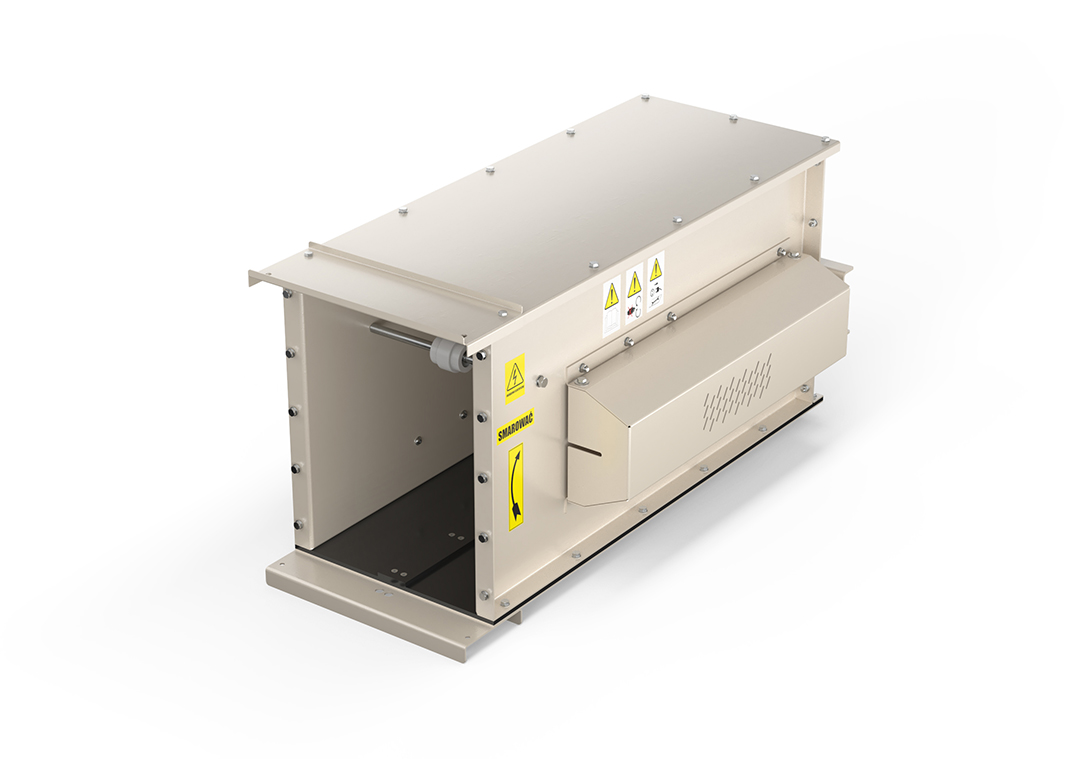

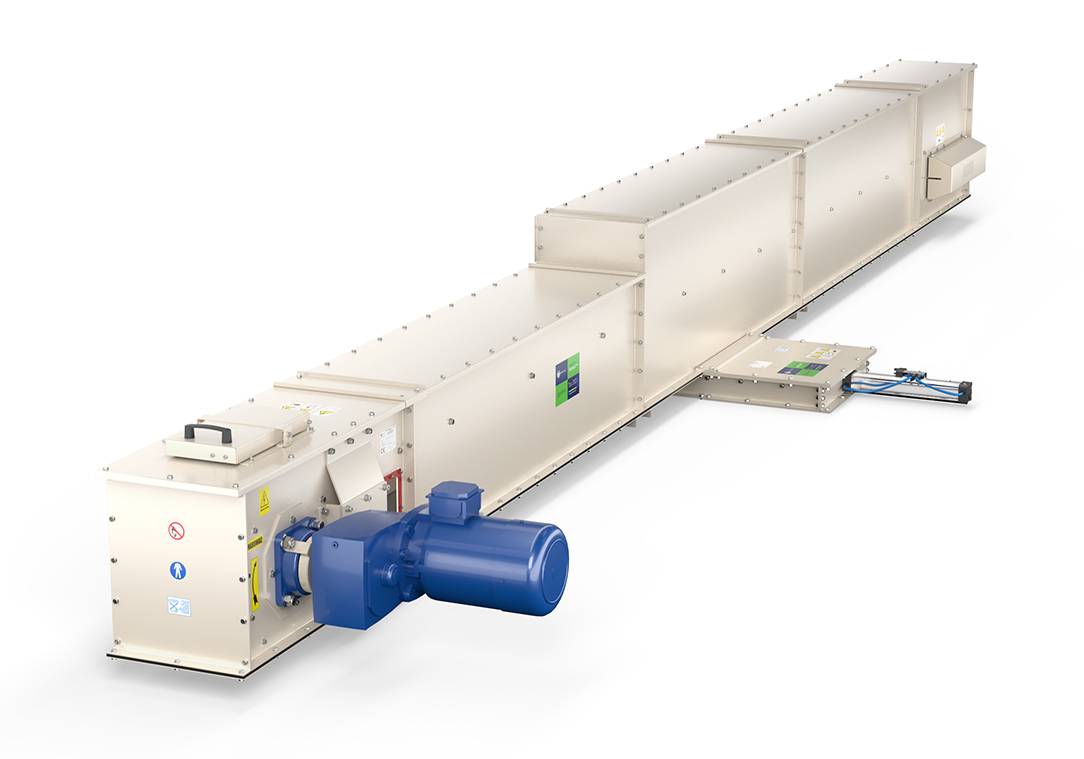

A chain conveyor (redler) is a device that is used both in agriculture and industry.

A chain conveyor (redler) is a device that is used both in agriculture and industry It is intended for horizontal transport of loose materials such as grains, pulses and oilseeds, sawdust, biomass and pellets.

The chain conveyor is made in three versions:

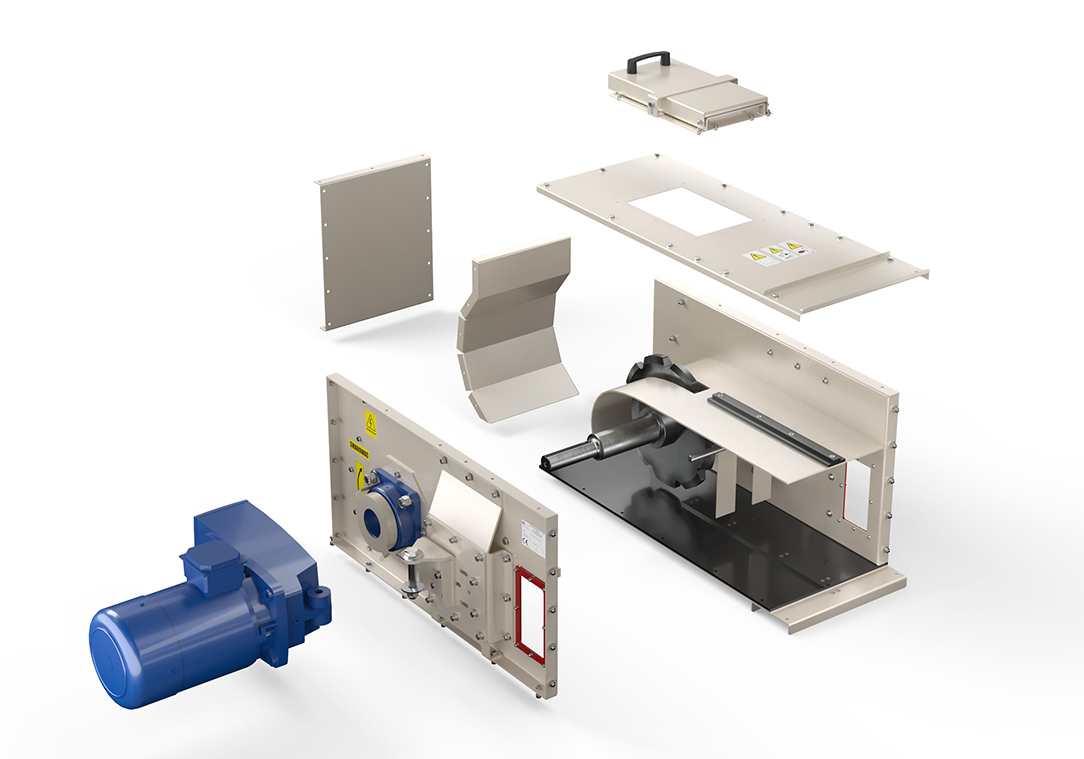

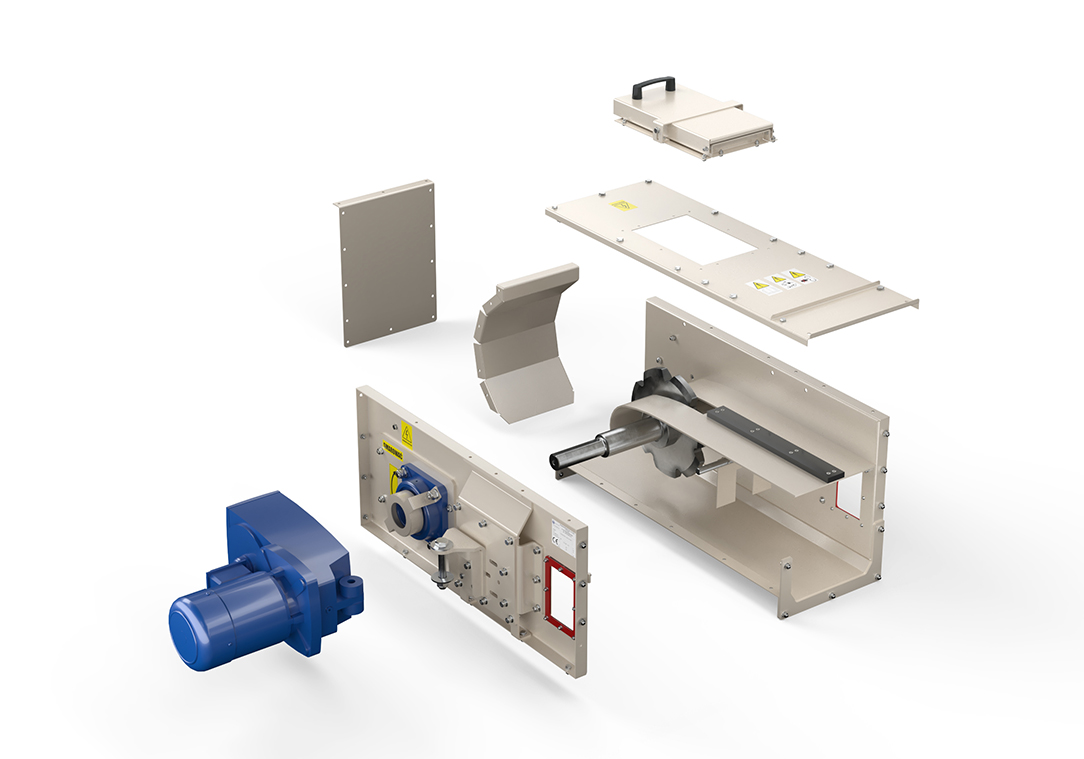

- ordinary (roller) conveyor – the material is conveyed along the bottom of the conveyor and the chain returns on rollers (3 rollers: two guiding, one supporting)

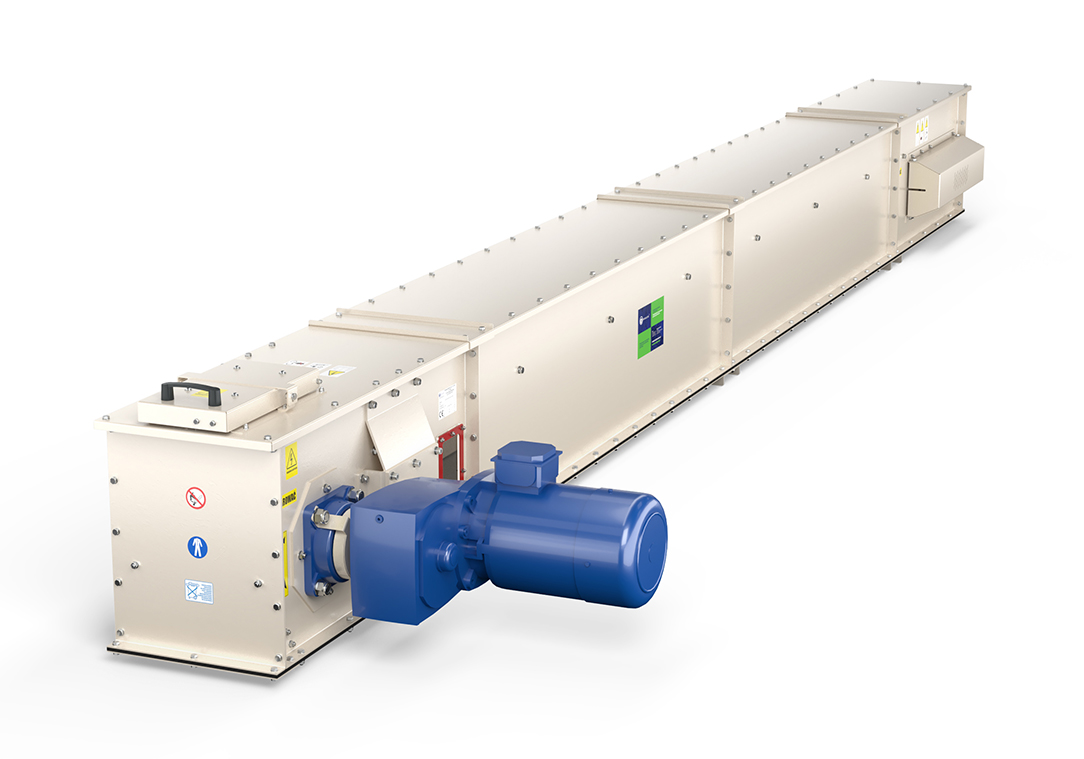

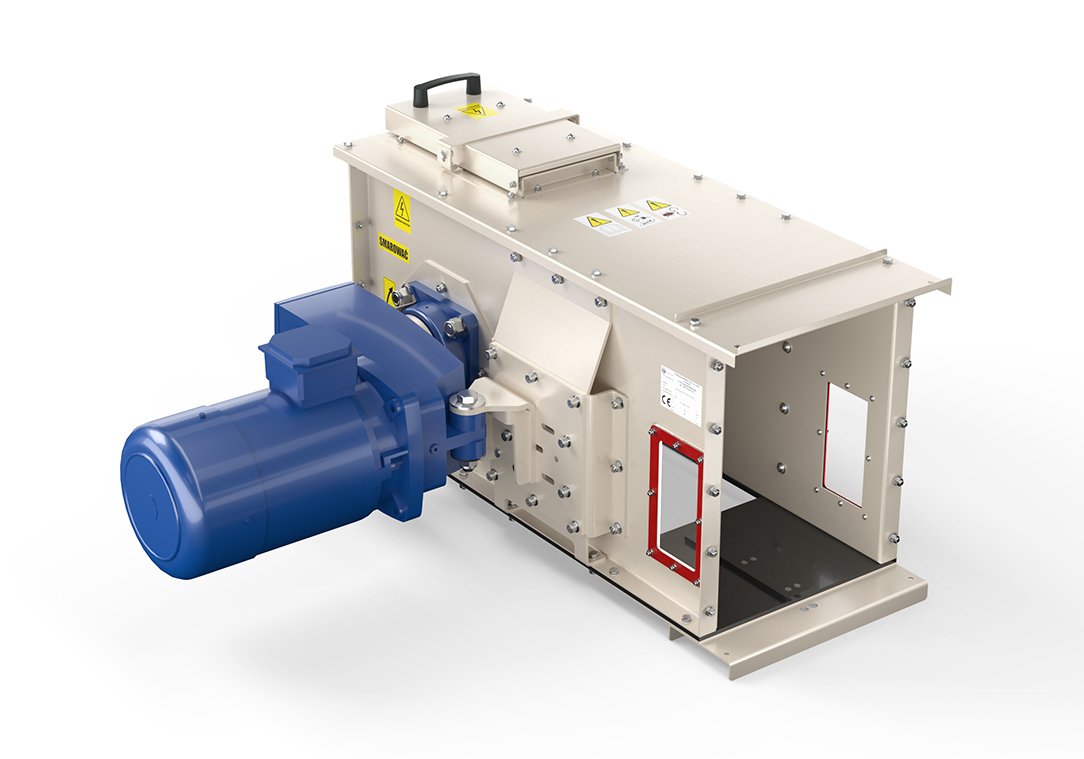

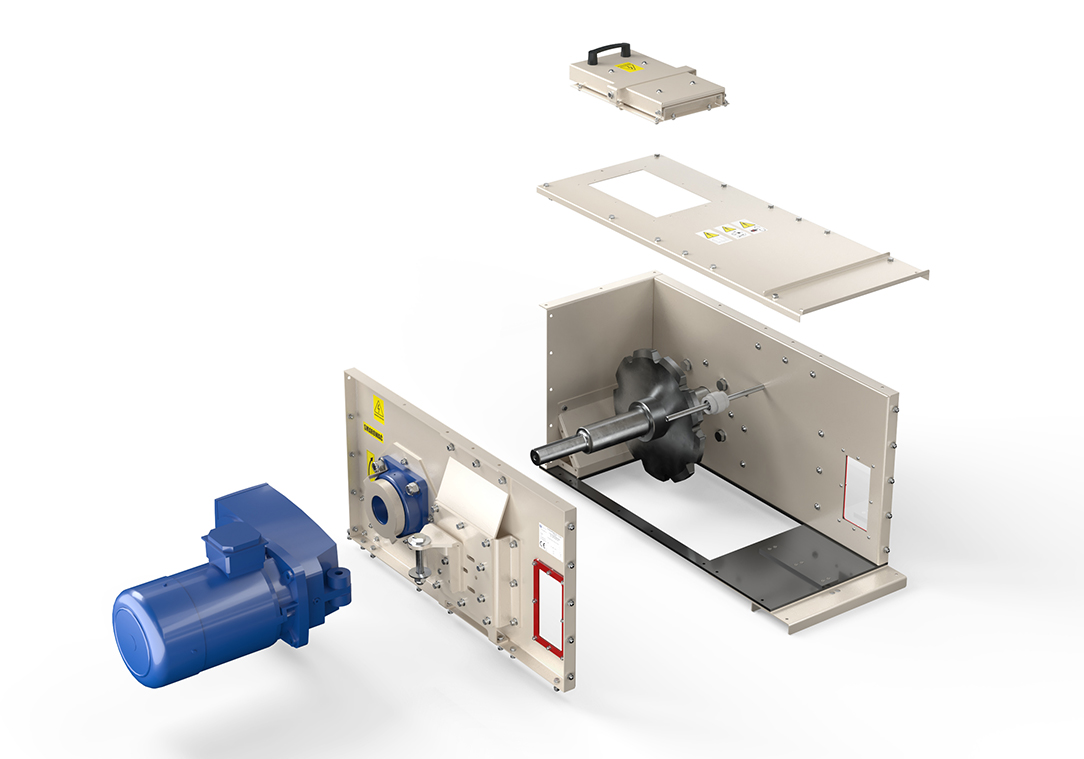

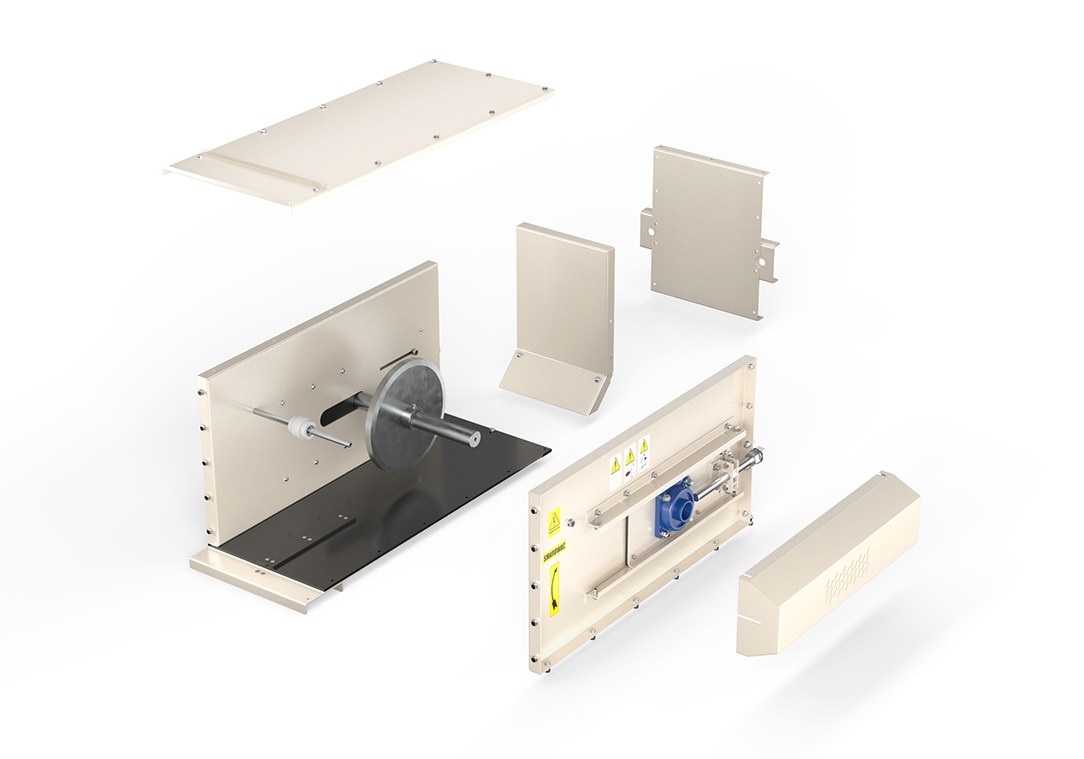

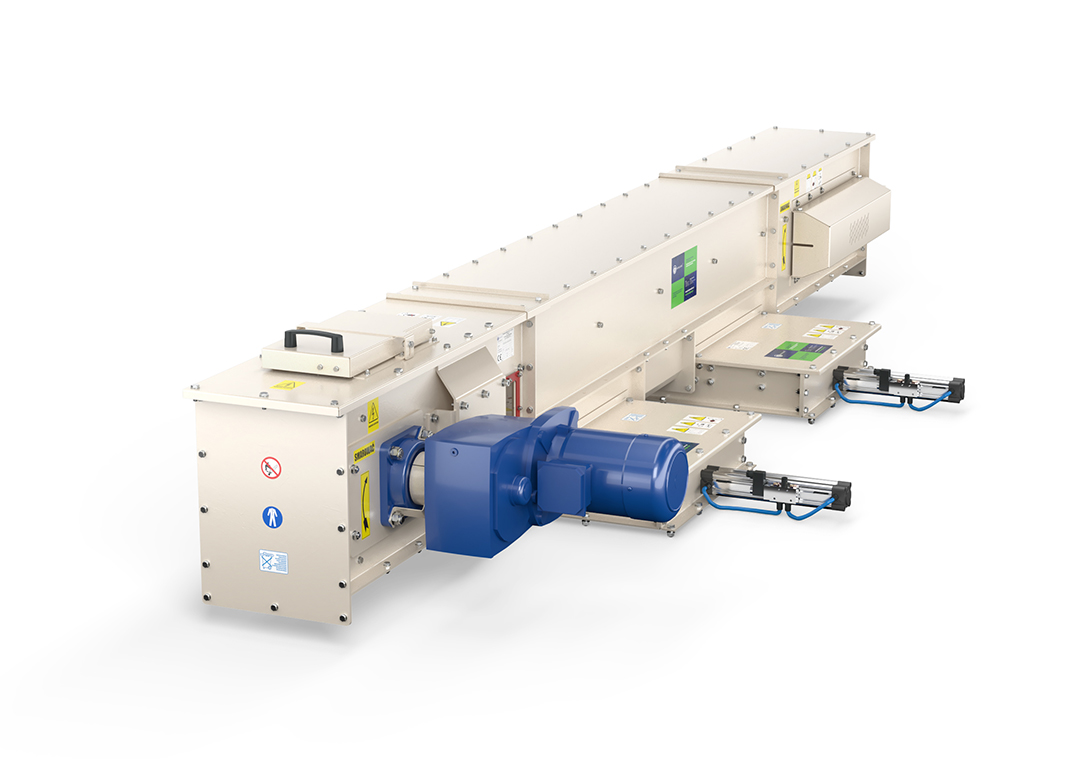

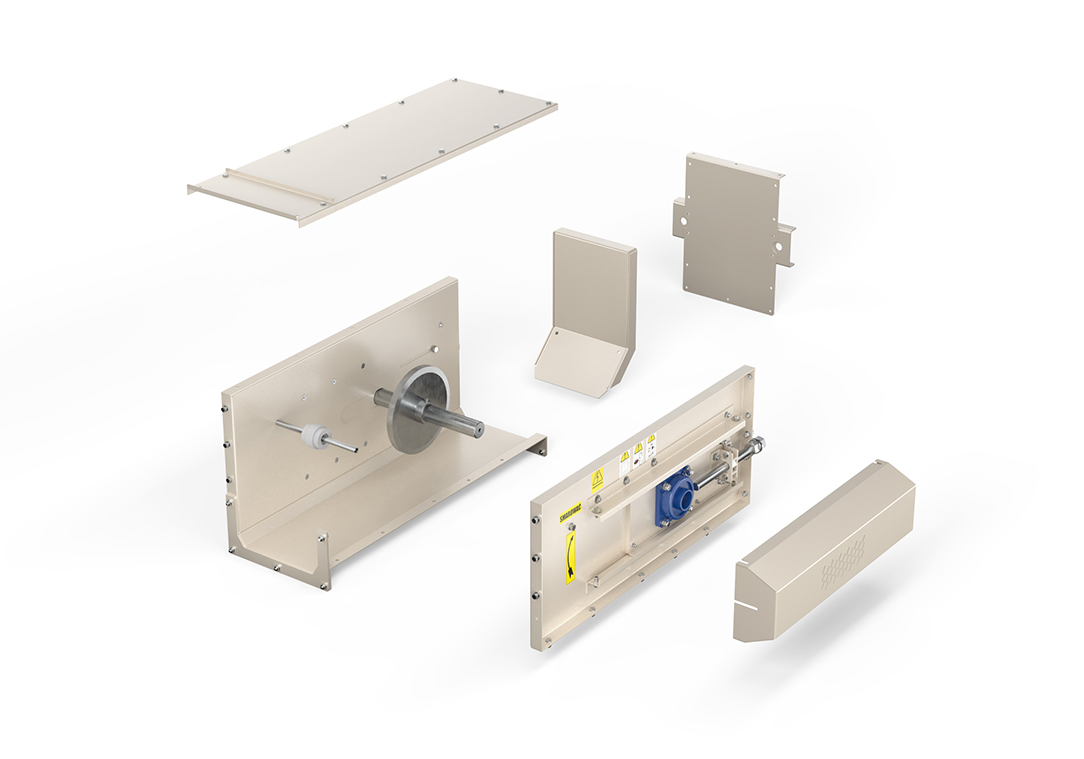

- self-cleaning conveyor (with a double bottom) – in this version there is an upper deck, along which the residues of the material return to be moved to the right discharge

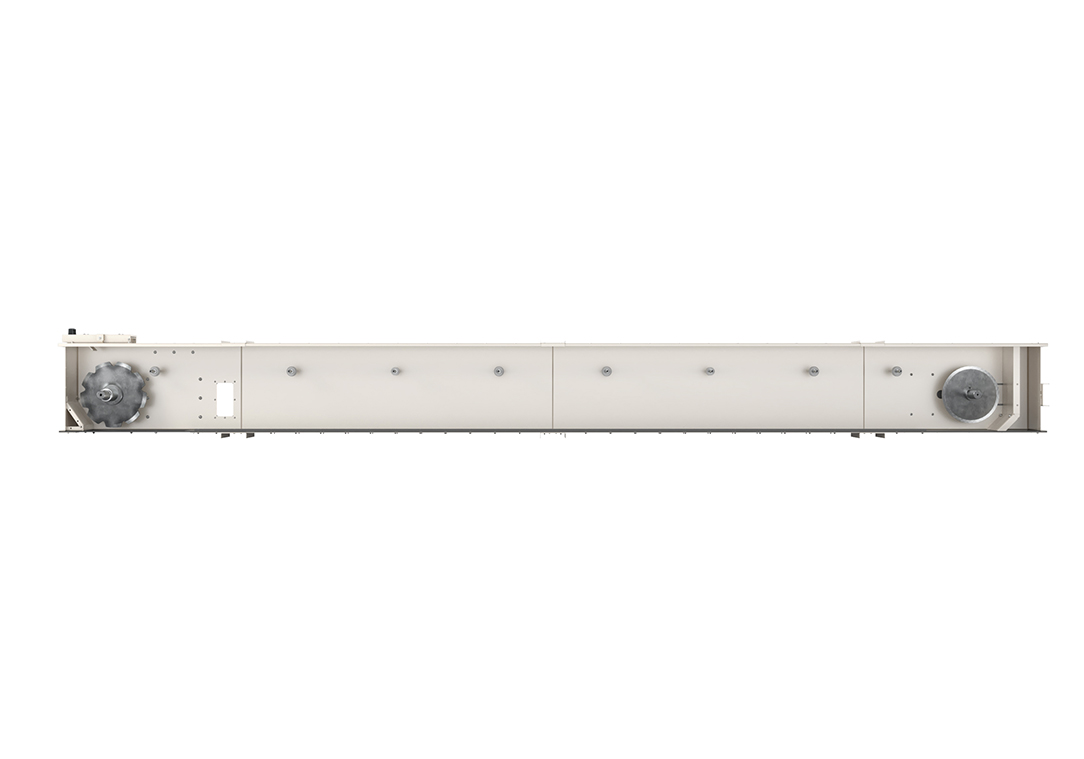

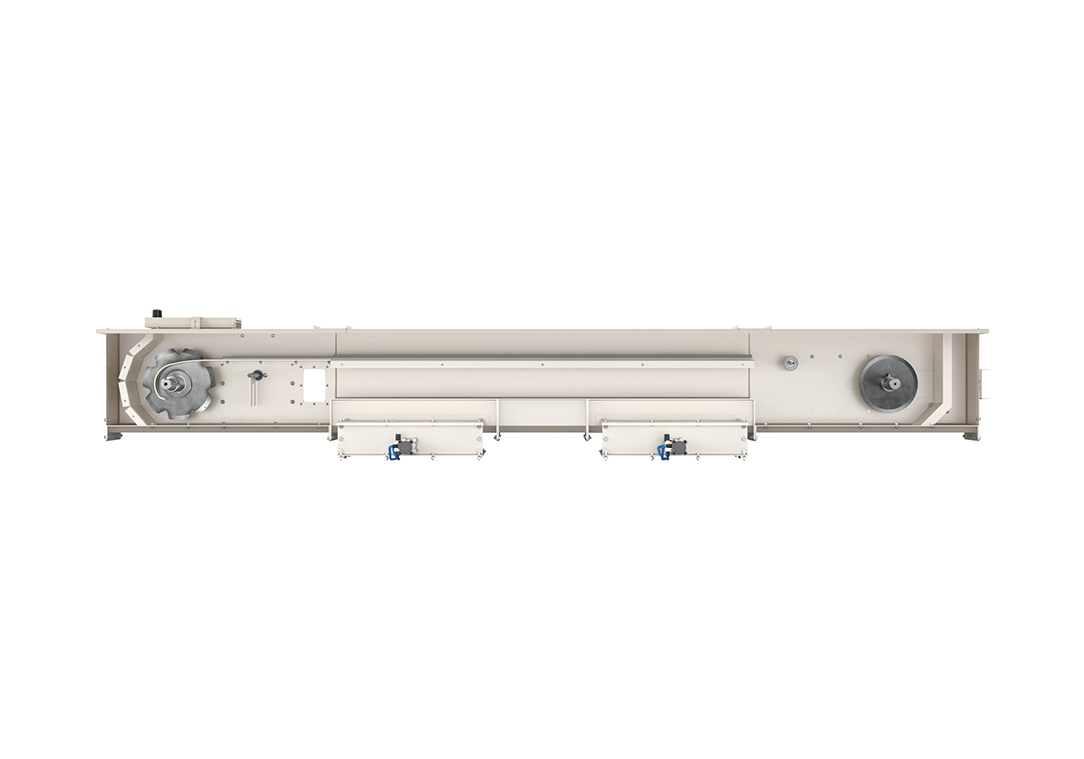

- elevated (bi-directional) conveyor – in the case of this type, owing to the greater height over the upper deck, it is possible to transport the raw material with full capacity along the upper and bottom deck

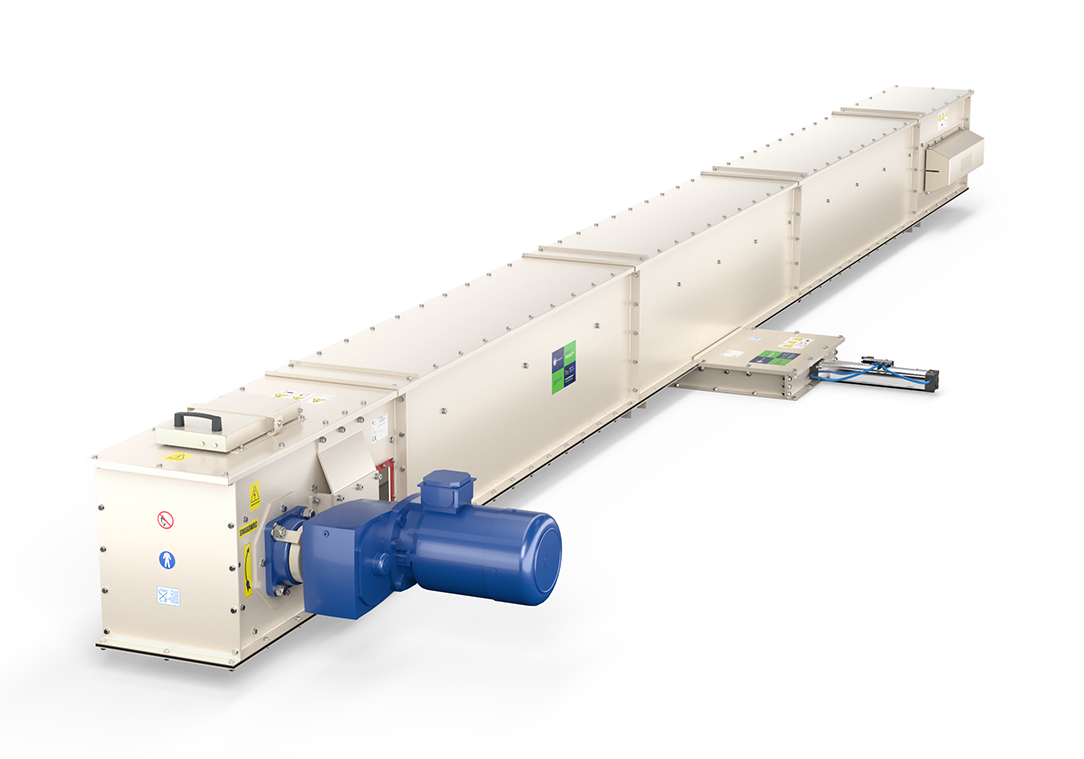

- conveyor with a sloped bottom, owing to which the it is characterised by high cleanliness during material transport (the design ensures a very good cleanability)

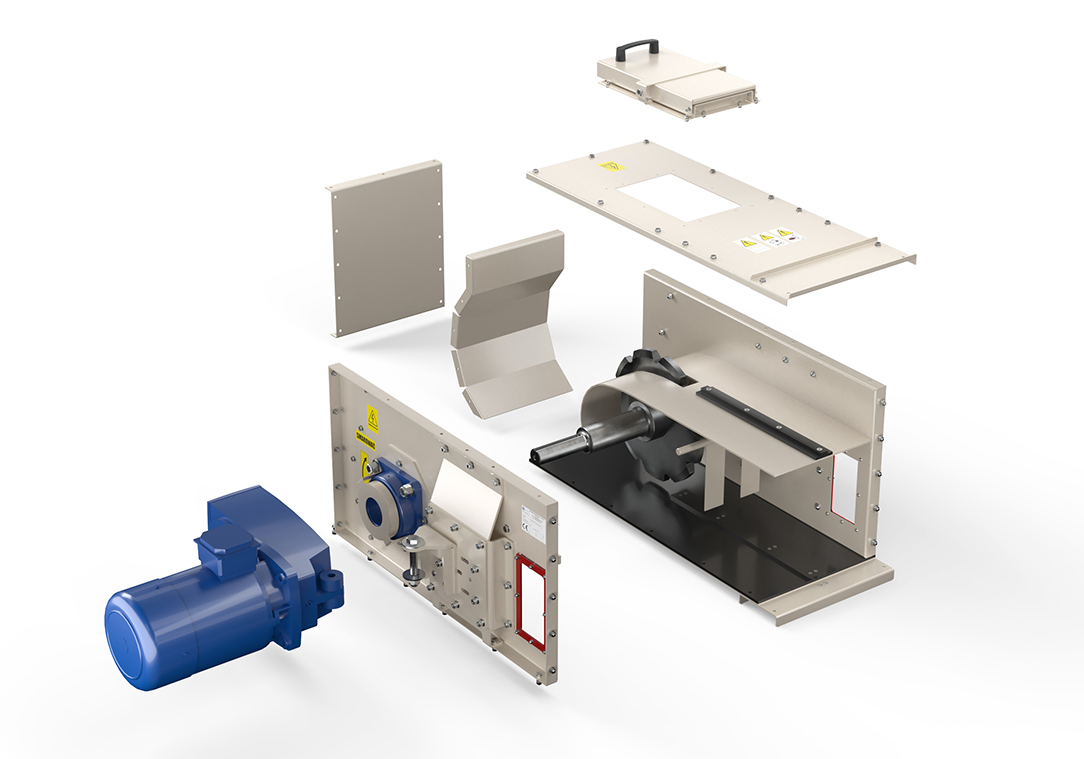

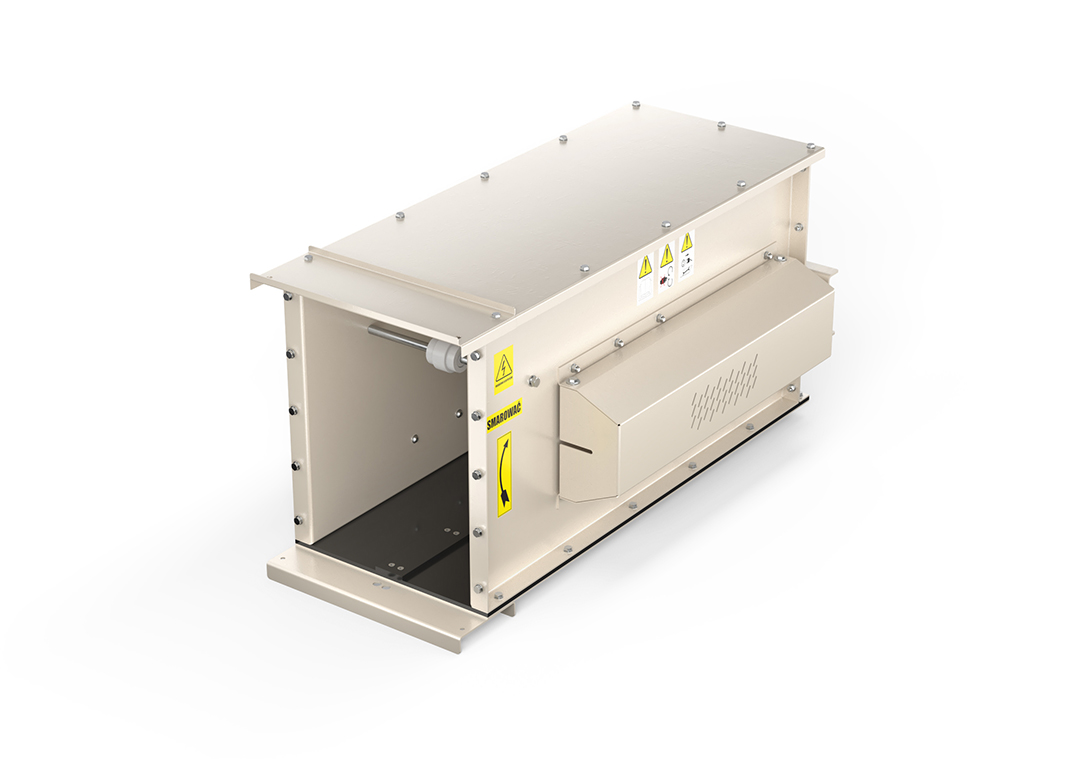

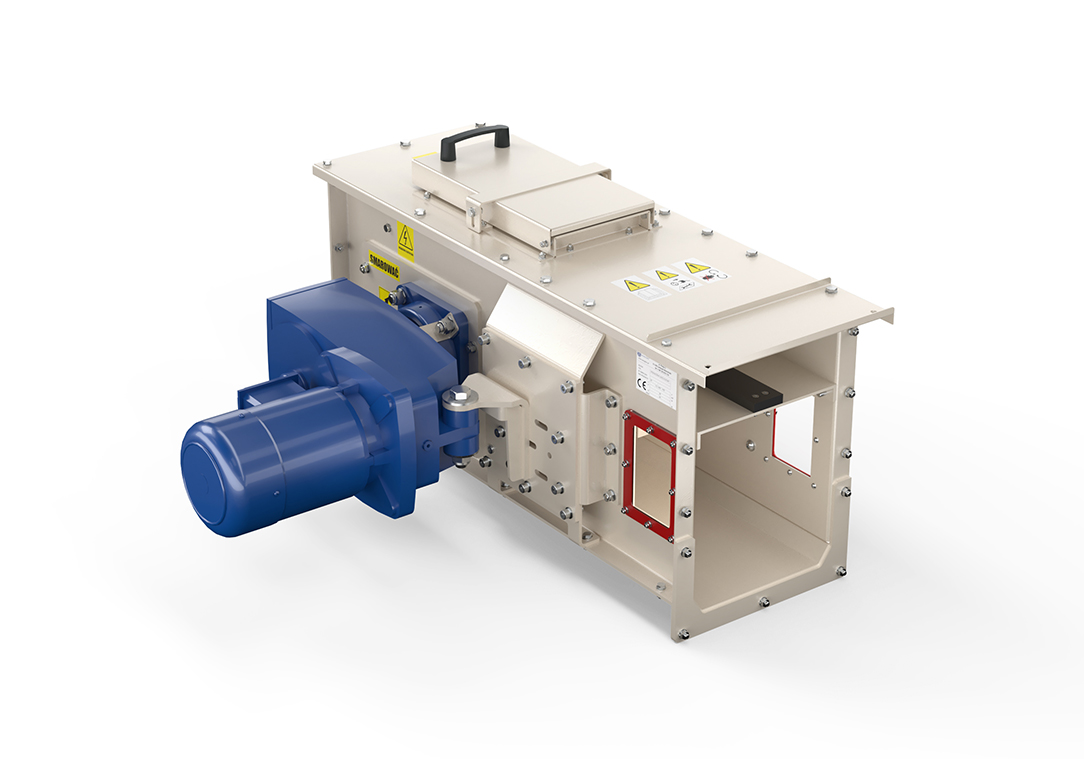

The device is assembled from ready-made modules such as drive station, troughs and return station. This allows for the manufacture of conveyors with different lengths, tailored to the requirements and needs of the Client. The bottom and the upper deck are lined with wear-resistant plastic, which increases the service life of the device and suppresses noise.

Chain conveyors are typically painted in RAL 1015.

Optionally, it is possible to use other colours.

At the Client’s request, the devices can be manufactured in the galvanised or stainless steel (acid-resistant) versions.

Roller chain conveyor

Roller chain conveyor

Roller chain conveyor

Roller chain conveyor

Roller chain conveyor

Roller chain conveyor

Roller chain conveyor

Roller chain conveyor

Roller chain conveyor

Roller chain conveyor

Roller chain conveyor

Roller chain conveyor

Roller chain conveyor

Roller chain conveyor

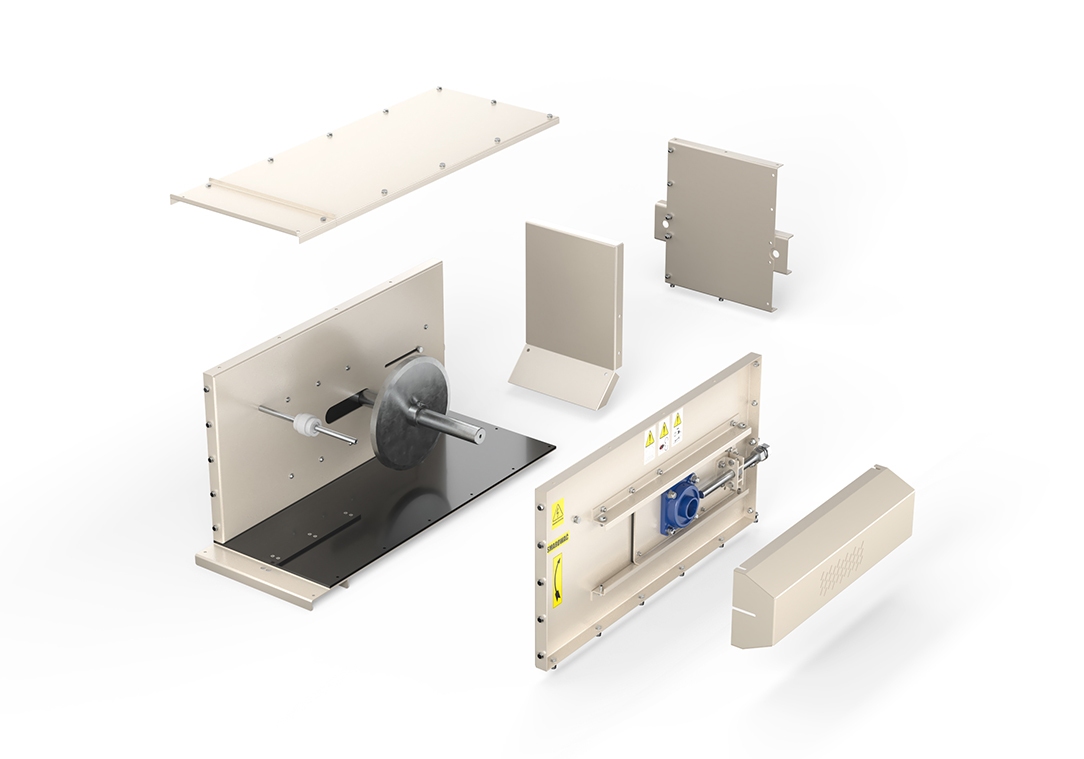

Self-cleaning chain conveyor (with a double bottom)

Self-cleaning chain conveyor (with a double bottom)

Self-cleaning chain conveyor (with a double bottom)

Self-cleaning chain conveyor (with a double bottom)

Self-cleaning chain conveyor (with a double bottom)

Self-cleaning chain conveyor (with a double bottom)

Self-cleaning chain conveyor (with a double bottom)

Self-cleaning chain conveyor (with a double bottom)

Self-cleaning chain conveyor (with a double bottom)

Self-cleaning chain conveyor (with a double bottom)

Self-cleaning chain conveyor (with a double bottom)

Self-cleaning chain conveyor (with a double bottom)

Self-cleaning chain conveyor (with a double bottom)

Self-cleaning chain conveyor (with a double bottom)

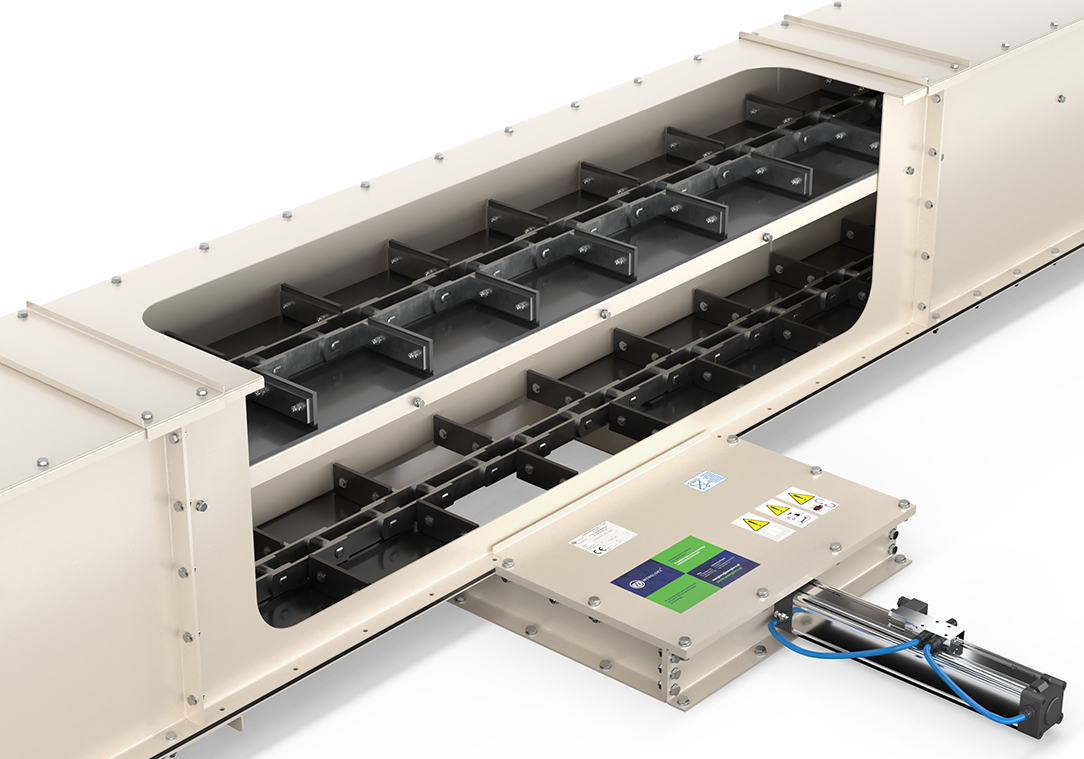

Elevated chain conveyor

Elevated chain conveyor

Elevated chain conveyor

Elevated chain conveyor

Elevated chain conveyor

Elevated chain conveyor

Elevated chain conveyor

Elevated chain conveyor

Elevated chain conveyor

Elevated chain conveyor

Elevated chain conveyor

Elevated chain conveyor

Elevated chain conveyor

Elevated chain conveyor

Chain conveyor with inclined bottom

Chain conveyor with inclined bottom

Chain conveyor with inclined bottom

Chain conveyor with inclined bottom

Chain conveyor with inclined bottom

Chain conveyor with inclined bottom

Chain conveyor with inclined bottom

Chain conveyor with inclined bottom

Chain conveyor with inclined bottom

Chain conveyor with inclined bottom

Chain conveyor with inclined bottom

Chain conveyor with inclined bottom

Chain conveyor with inclined bottom

Chain conveyor with inclined bottom