Production

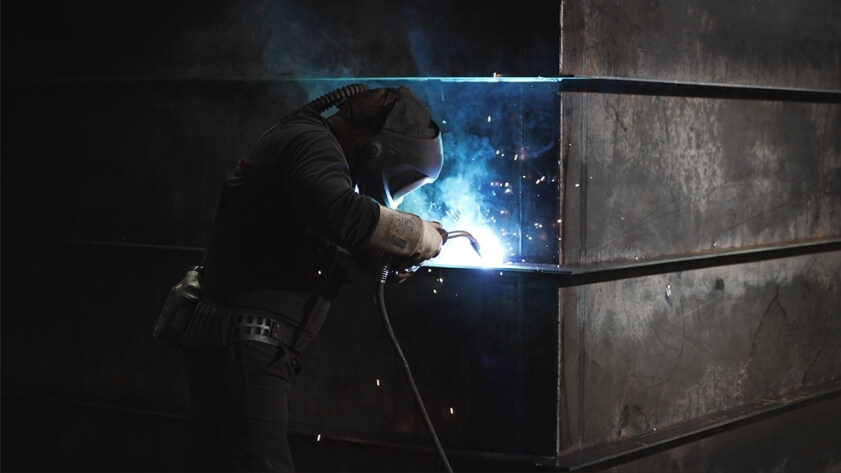

Our leading position on the Polish market and full indpendence would never have been achieved without our own production plant. This is where the solutions designed by the #Wenglorz Expert engineering team are transformed into top quality finished products.

TOP-CLASS

SUPPORT

FACILITIES

TOP-CLASS

SUPPORT

FACILITIES

As representatives of heavy industry, we pay particular attention to such issues as occupational safety and hygiene. We use only certified equipment, conduct regular staff training, and provide specialised personal protection equipment, because the health and safety of the #WenglorzTeam are most important to us.

This is possible owing to our modern machinery park, experienced and competent staff and certificates which confirm the quality of the work which we perform.

The process and conveying equipment, steel structures and other elements of technological lines which are widely recognised and appreciated by the leading players of the agro-food market are manufactured on an area of over 35,000 m2.

In connection with the necessity of using harmful and hazardous substances in the technological processes, we place great emphasis on the protection of employees and the working environment from their adverse effects, in accordance with the applicable legal requirements.

OUR PRODUCTS

A chain conveyor (redler) is a device that is used both in agriculture and industry.

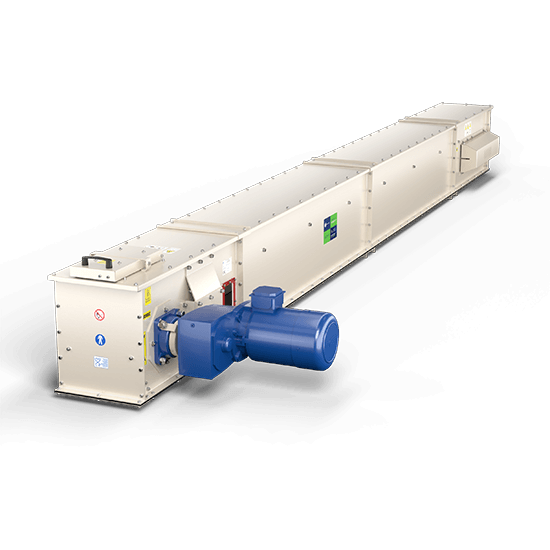

A screw conveyor is a device that is used both in agriculture and industry.

A bucket elevator is a device that is used both in agriculture and industry.

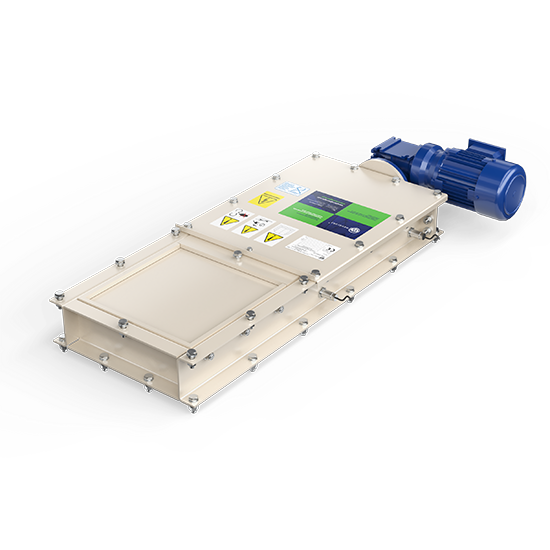

Slide gates are devices used to close/open outlets from bins, chain conveyors and other process equipment within process lines.

Valve boxes are used to manage the flow of loose materials (grains, pulses, oilseeds, biomass and pellets) which fall by gravity and which are fed to its inlet channel.

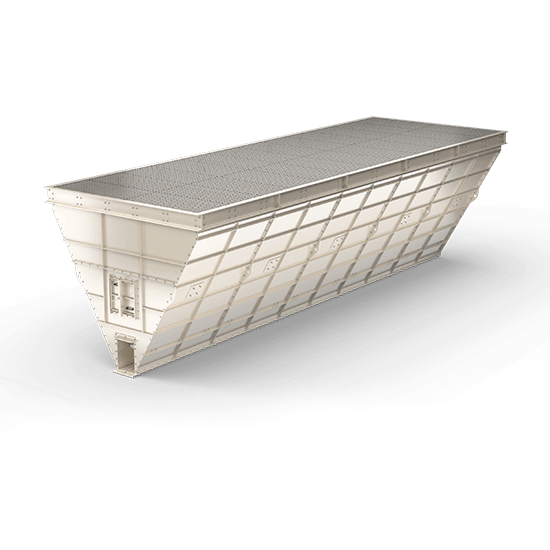

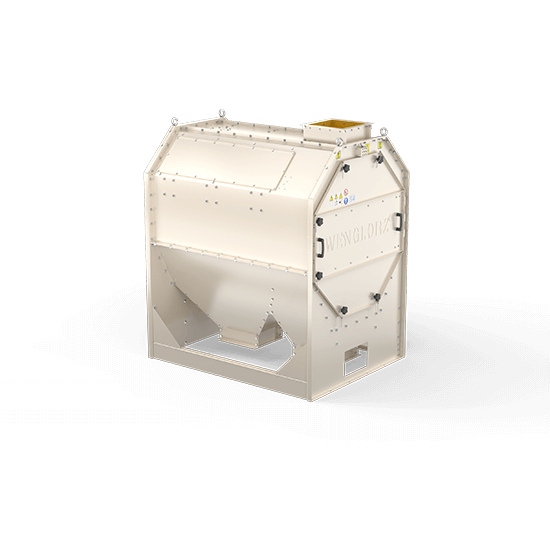

The intake hopper is used to receive bulk materials in grain warehouses, compound feed plants and other related industries.

The hydraulic dumper is used to unload material from entire sets of vehicular transport (with a mass of 50 tonnes and length up to 18 m) in order to empty its content to the intake hopper.

The additive hopper is used to replenish the material in tanks from bags and big-bags.

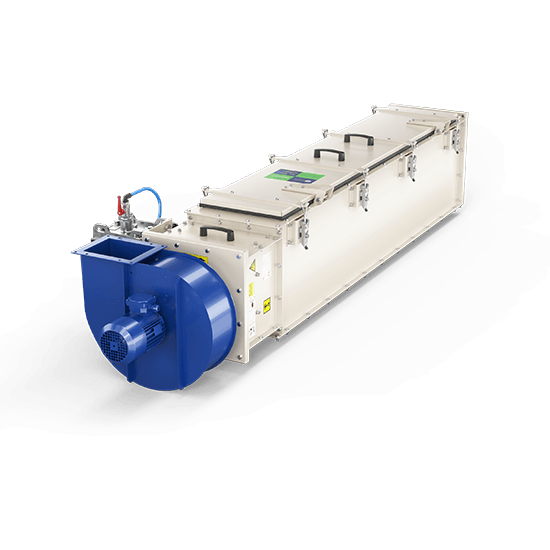

An aspiration filter (pulse-jet, fabric filter - also referred to as a dust filter) is used to remove dry and non-adhesive dust from air and gases in a decentralised system.

A drum screener is used for the preliminary sifting of the material intended for production, coarse pollutants such as stones, pieces of plants, strings or wire, etc.

The rotary screener is used to separate lumps, fine fractions from pellet, etc. in such a way as to prevent undesirable fractions, especially dust, from entering into the final product.

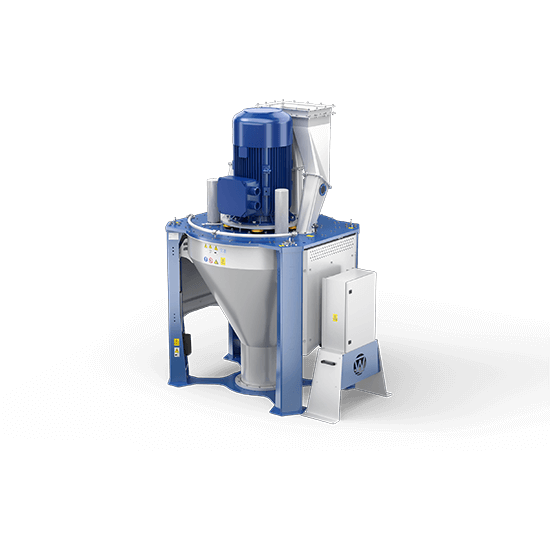

A vertical hammer mill is used to grind such components as grains, pulses and oilseeds.