Aspiration filter

An aspiration filter (pulse-jet, fabric filter - also referred to as a dust filter) is used to remove dry and non-adhesive dust from air and gases in a decentralised system.

An aspiration filter (pulse-jet, fabric filter – also referred to as a dust filter) is used to remove dry and non-adhesive dust from air and gases in a decentralised system. In the agri-food industry, the aspiration filter is used for aspiration of intake hoppers, hammer mills, bucket elevators, chain conveyors, bins, etc. It may be installed both in a production hall and outdoors.

Typically, it is available in a version painted in RAL1015. Other versions are available at special request after consultations.

Advantages of the device

- no losses of processed material – the filtered dust returns to the production cycle

- energy savings – the filter operates only when the aspirated equipment (de-dusted by the filter) is in use

- it reduces the risk of fire or dust explosion

- the existing dust removal system can be easily extended.

Design

- a 0.75kW or 2.2kW fan (depending on the size of the filter and its intended use)

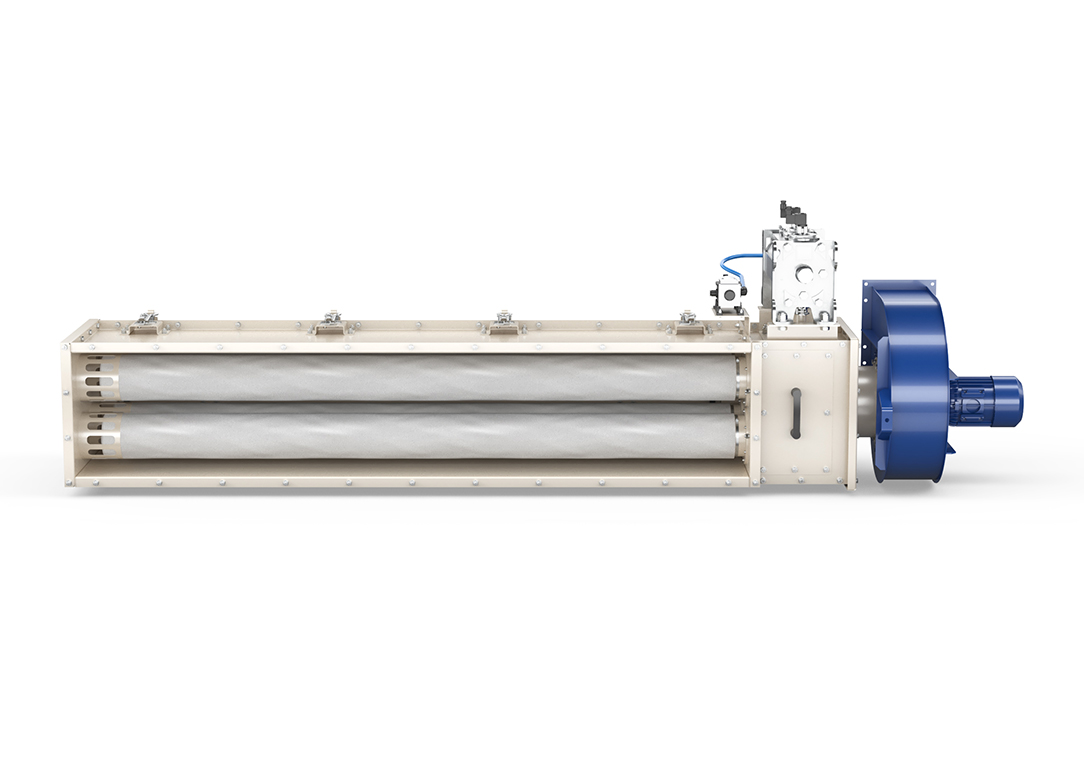

- working chamber with a filter sleeve

- air suction system

- pulse-jet regeneration system for filter sleeves.

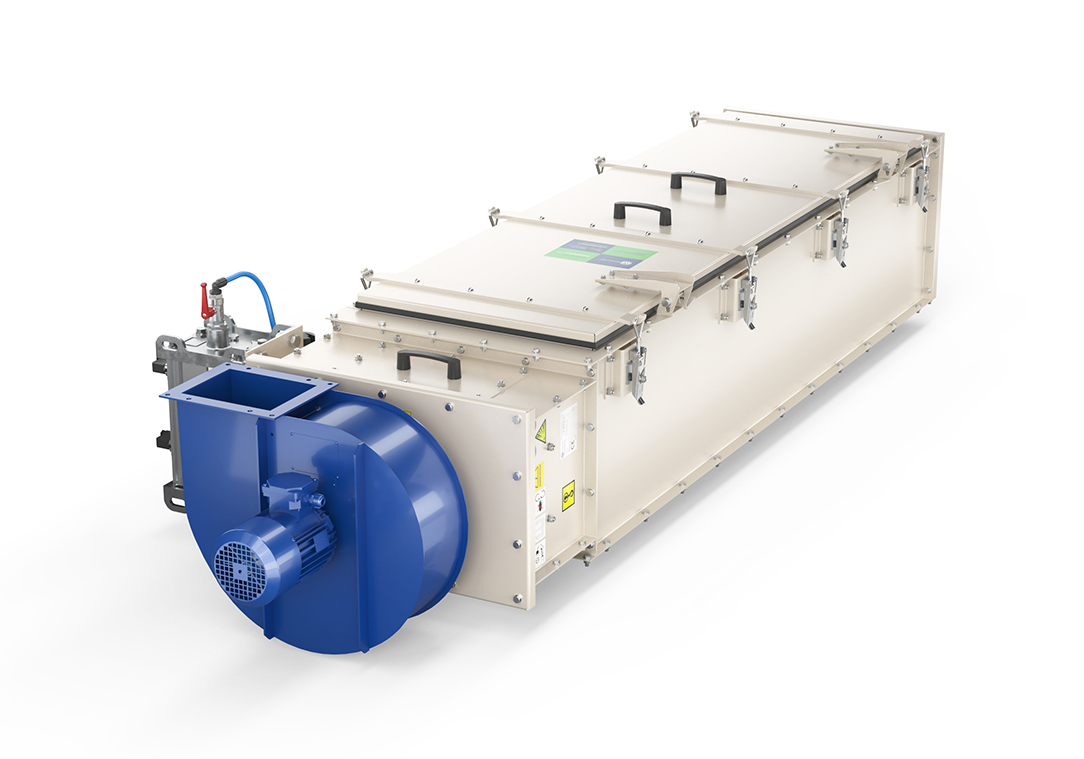

Taking into account the design and manner of installation, we can distinguish horizontaly (lying) filters and vertical (standing) filters.

Typically, the filters are manufactured in versions with four, six and nine sleeves. The filters used are 1.2 m or 1.8 m long.

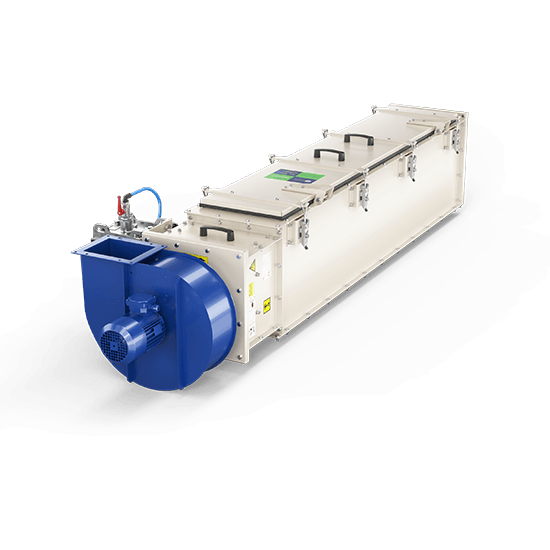

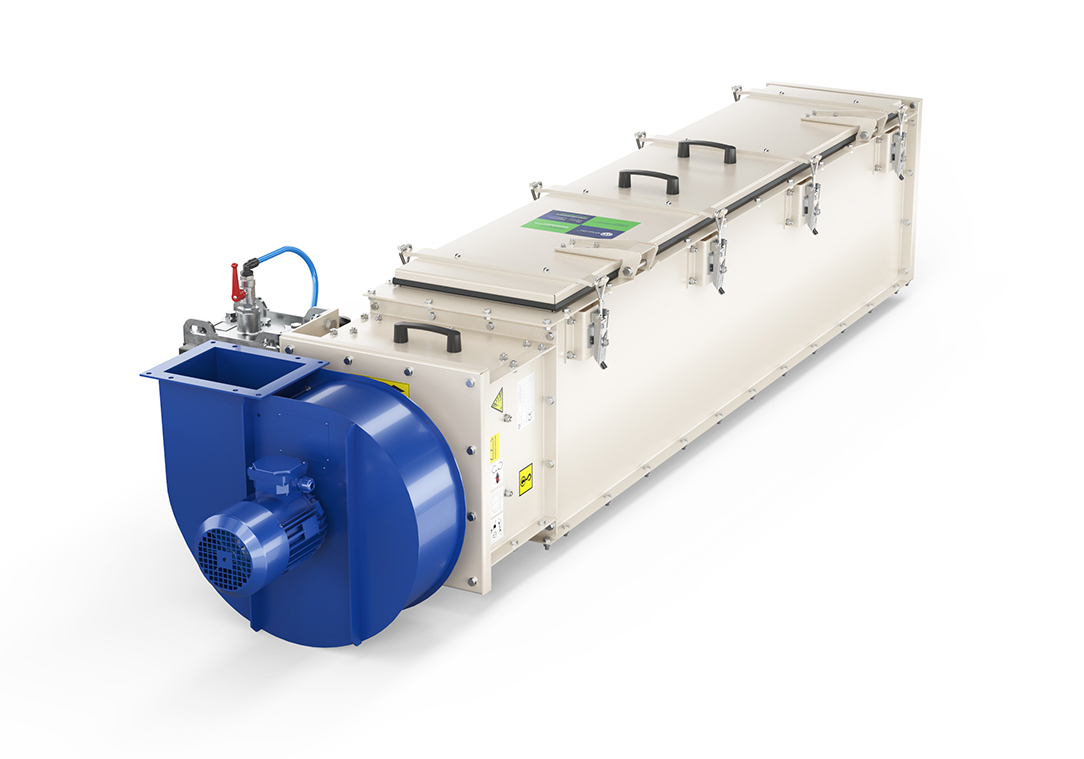

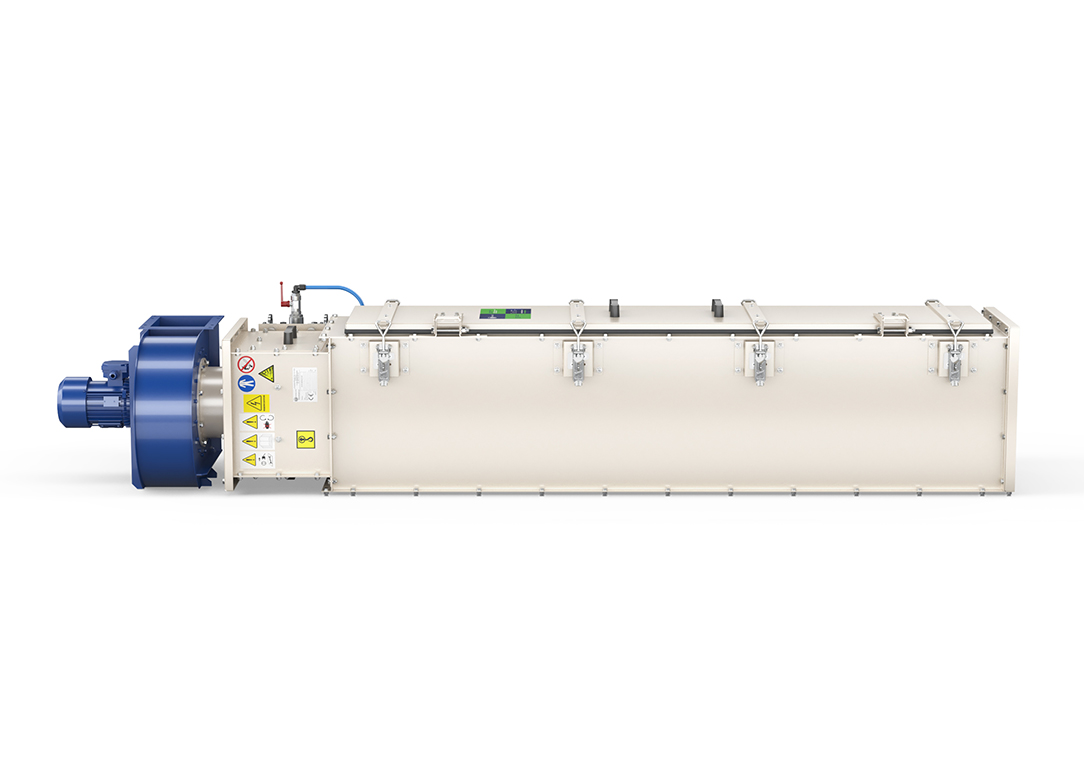

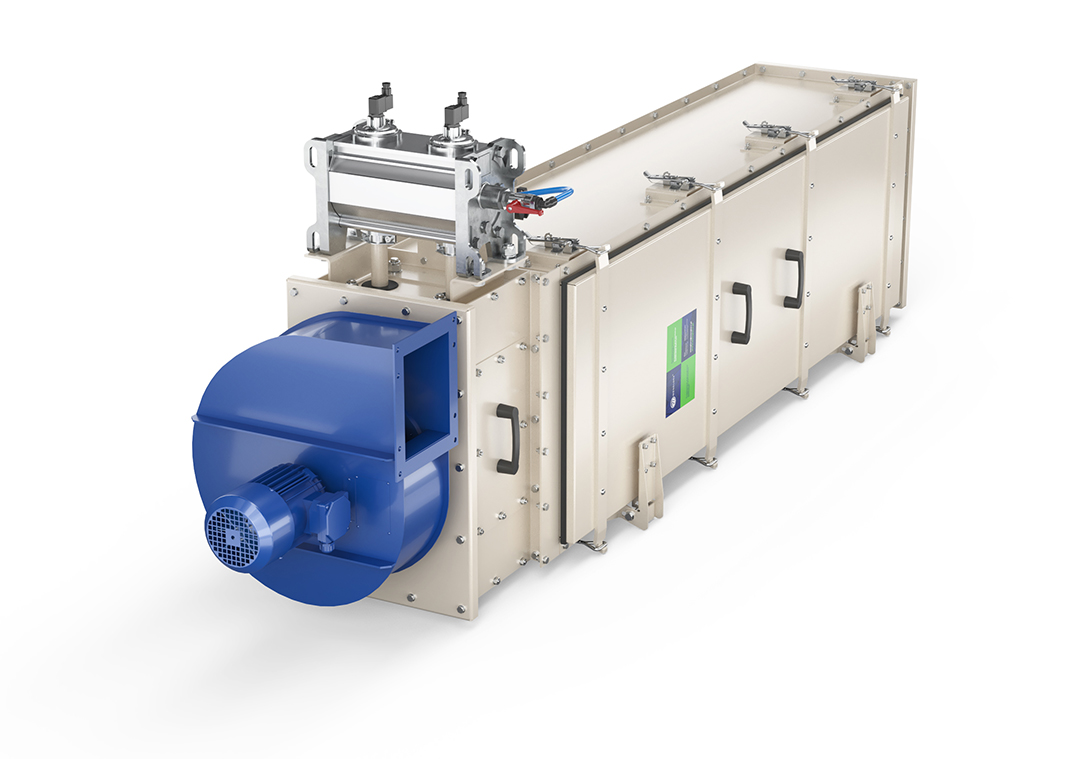

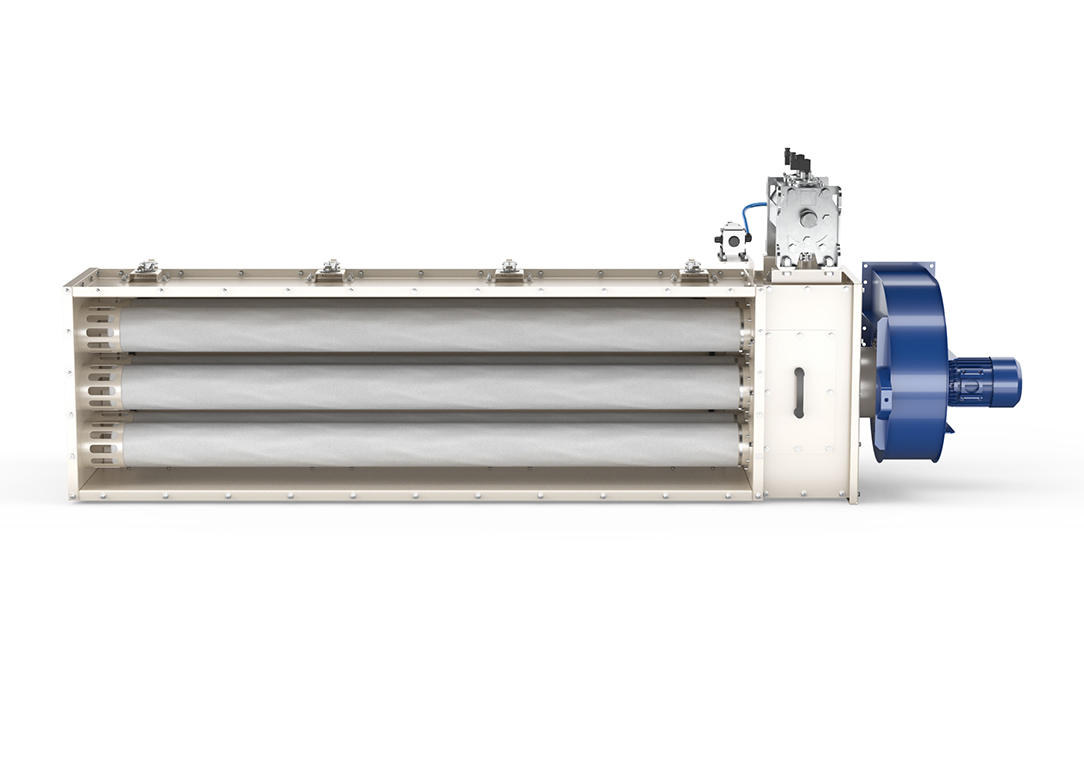

Horizontal aspiration filter

Horizontal aspiration filter

Horizontal aspiration filter

Horizontal aspiration filter

Horizontal aspiration filter

Horizontal aspiration filter

Horizontal aspiration filter

Horizontal aspiration filter

Horizontal aspiration filter

Horizontal aspiration filter

Horizontal aspiration filter

Horizontal aspiration filter

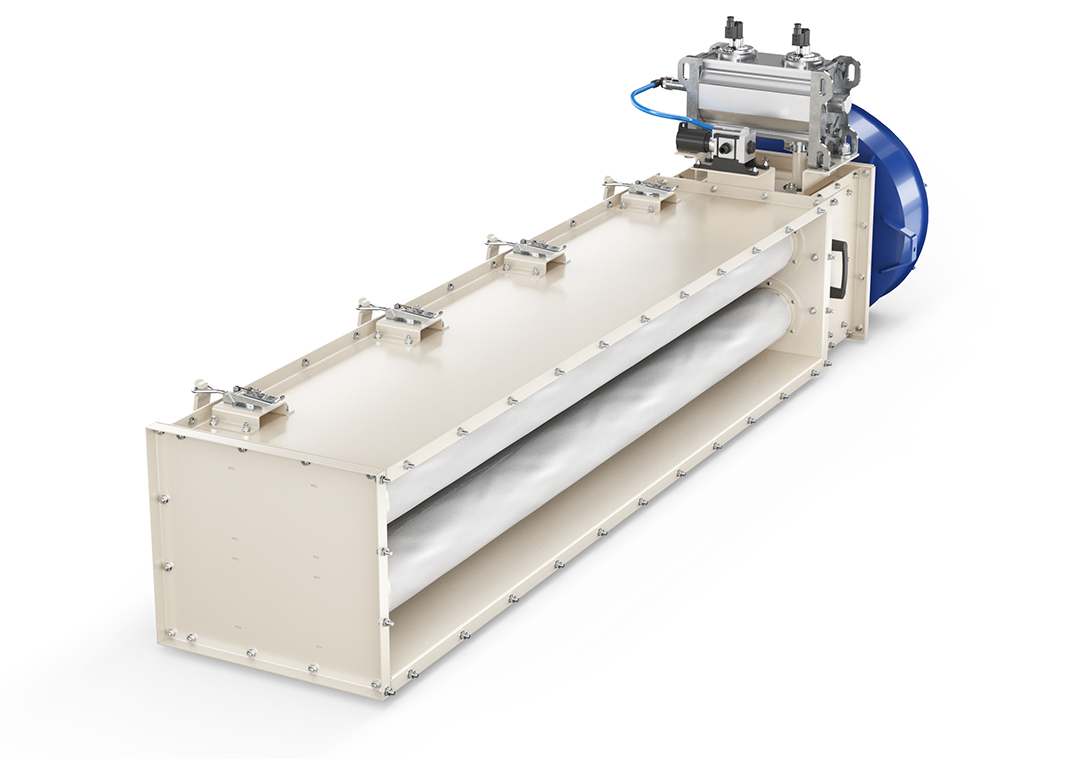

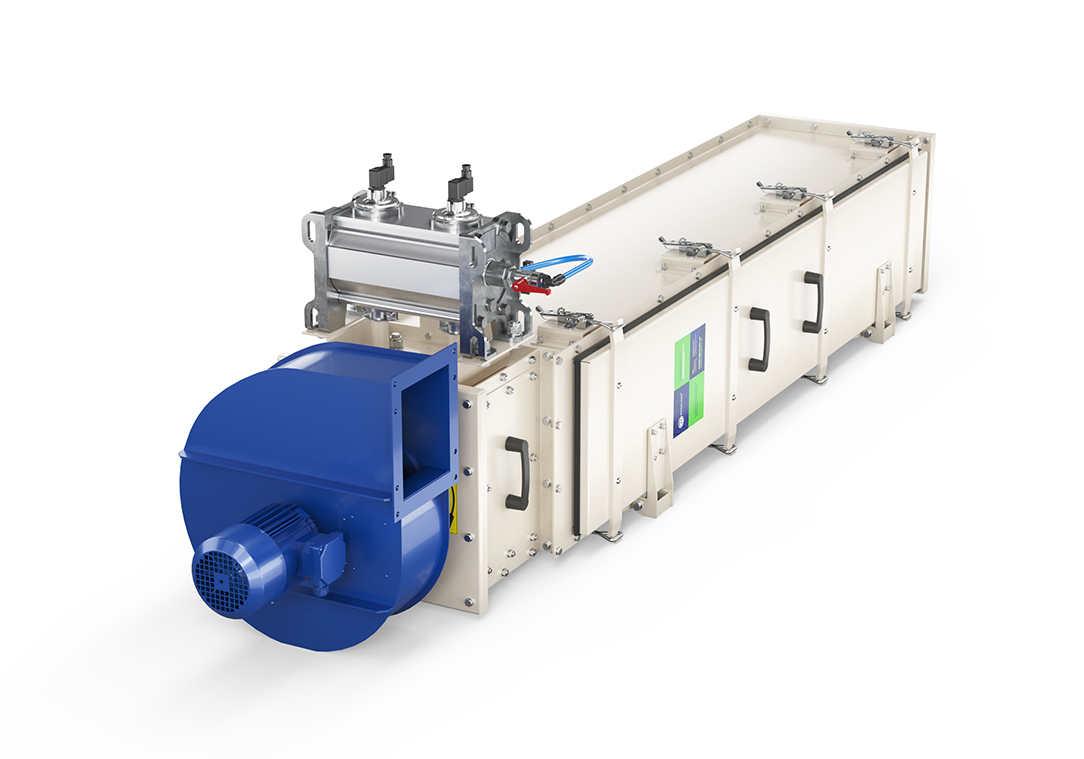

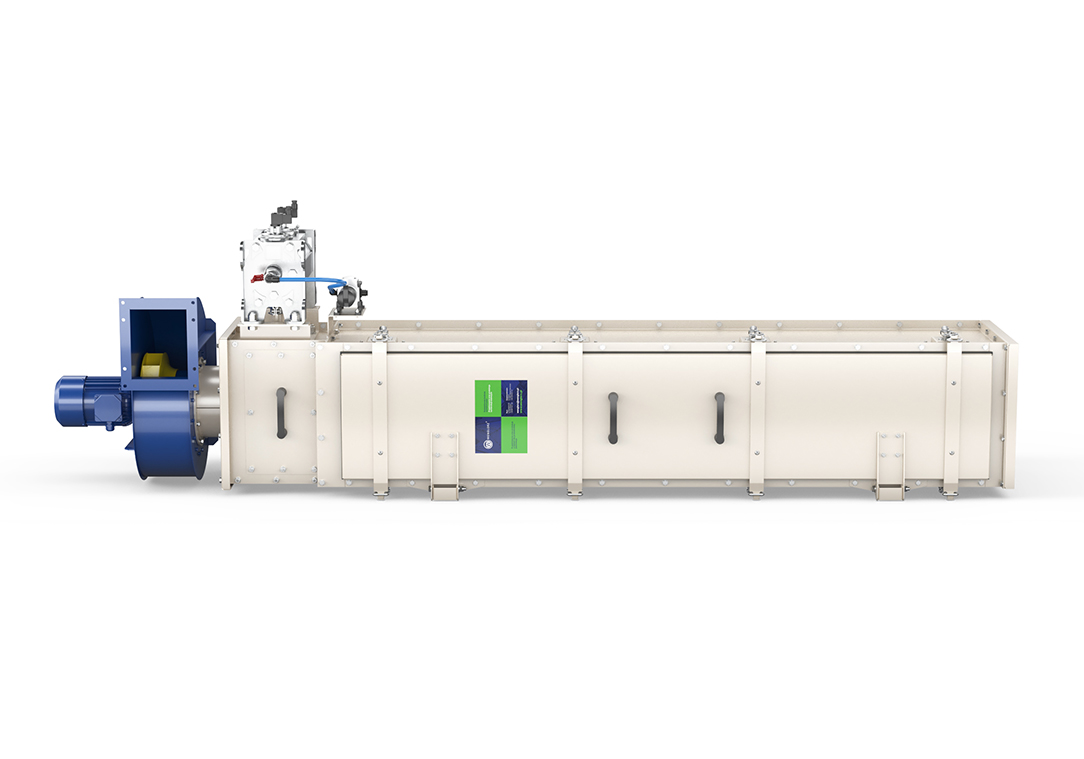

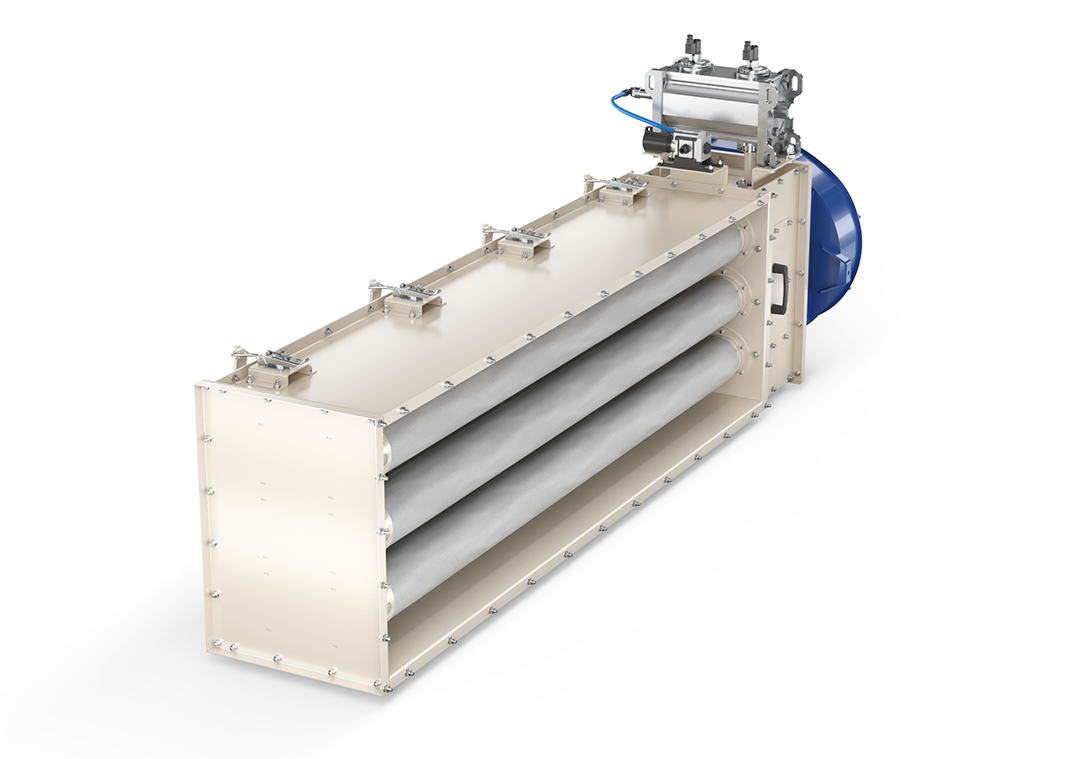

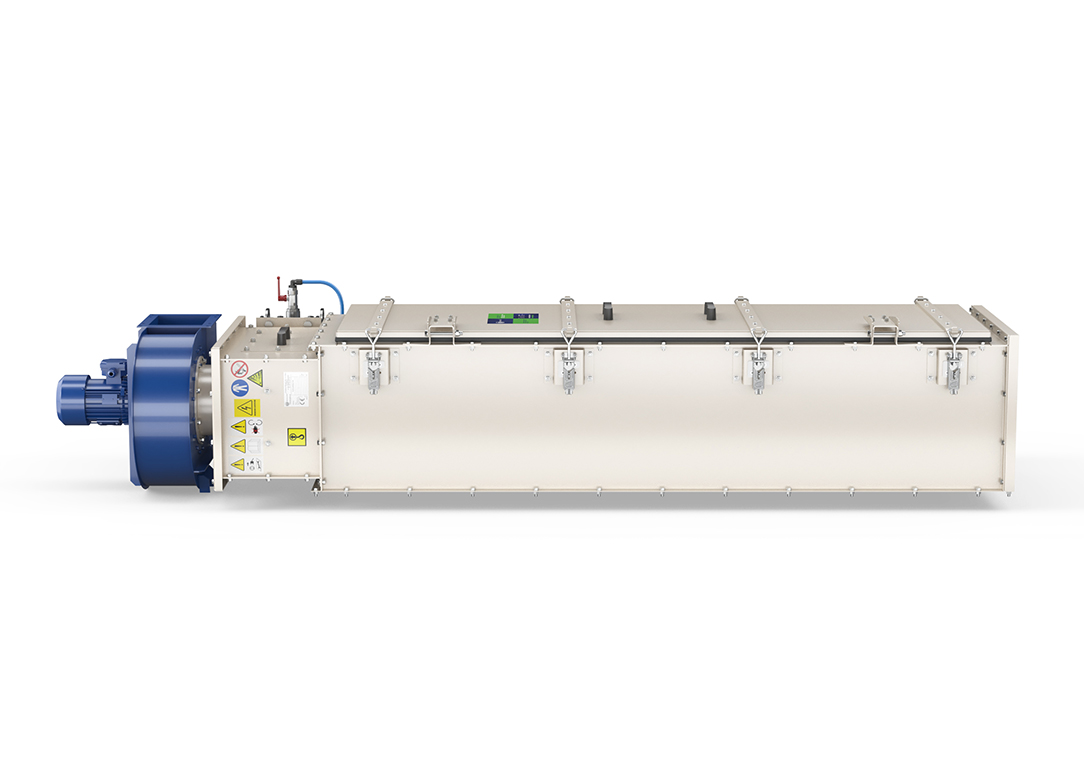

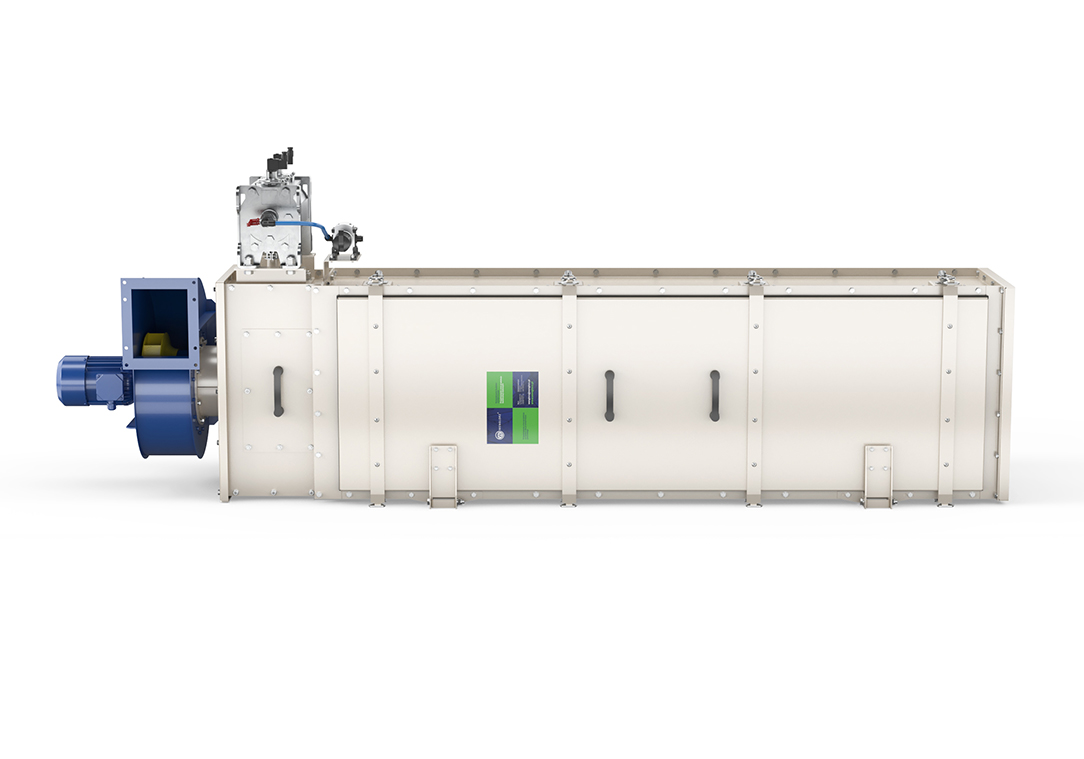

Horizontal aspiration filter 3x2

Horizontal aspiration filter 3x2

Horizontal aspiration filter 3x2

Horizontal aspiration filter 3x2

Horizontal aspiration filter 3x2

Horizontal aspiration filter 3x2

Horizontal aspiration filter 3x2

Horizontal aspiration filter 3x2

Horizontal aspiration filter 3x2

Horizontal aspiration filter 3x2

Horizontal aspiration filter 3x2

Horizontal aspiration filter 3x2

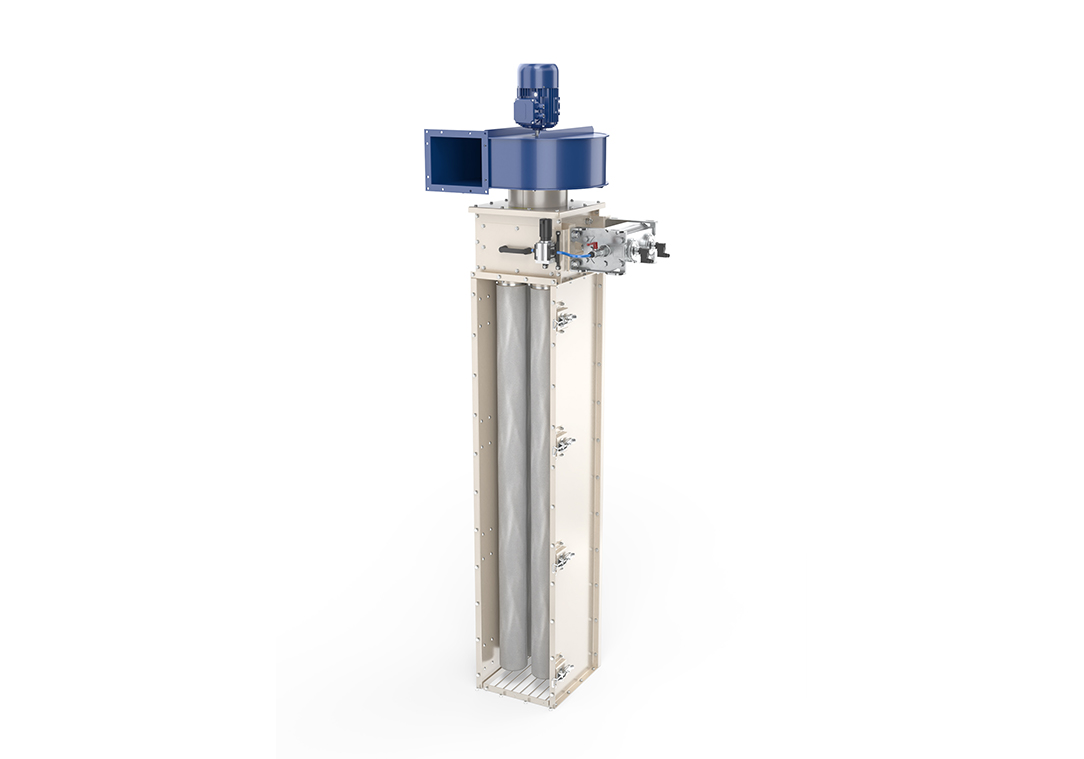

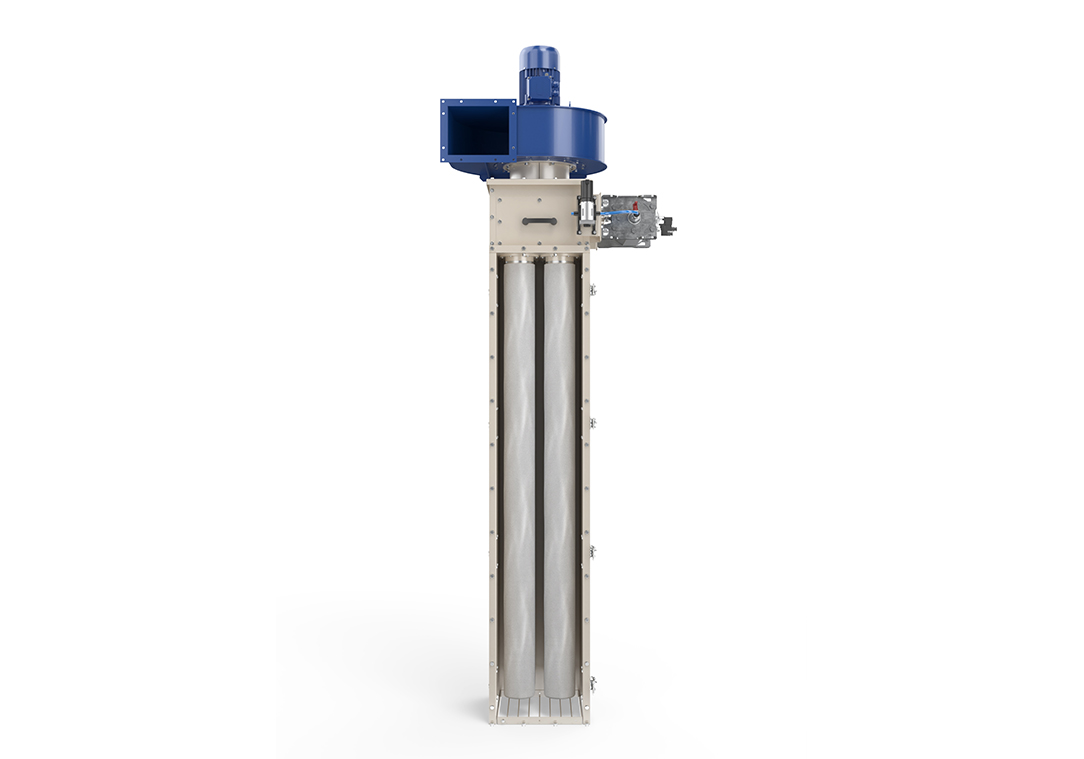

Vertical Aspiration Filter

Vertical Aspiration Filter

Vertical Aspiration Filter

Vertical Aspiration Filter

Vertical Aspiration Filter

Vertical Aspiration Filter

Vertical Aspiration Filter

Vertical Aspiration Filter