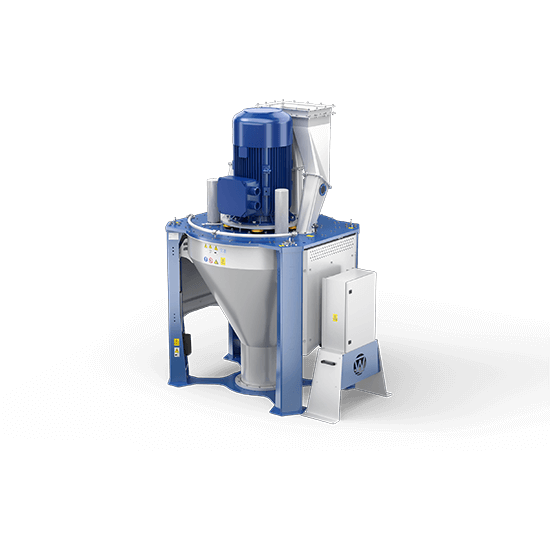

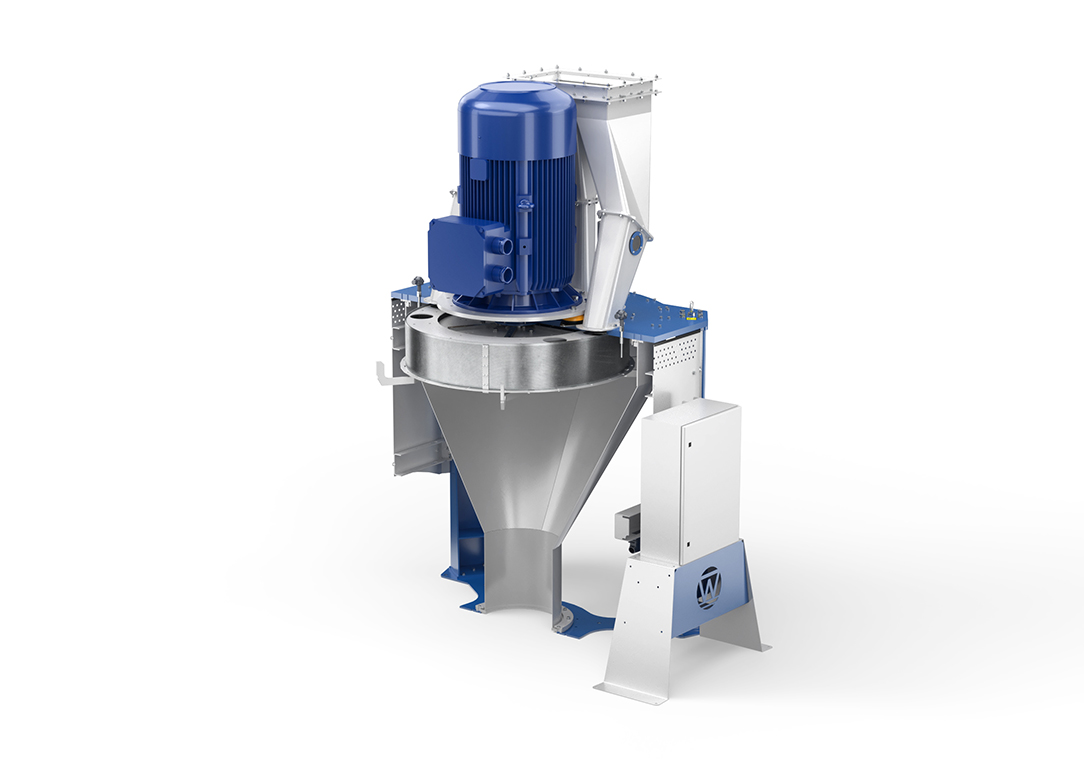

Vertical hammer mill

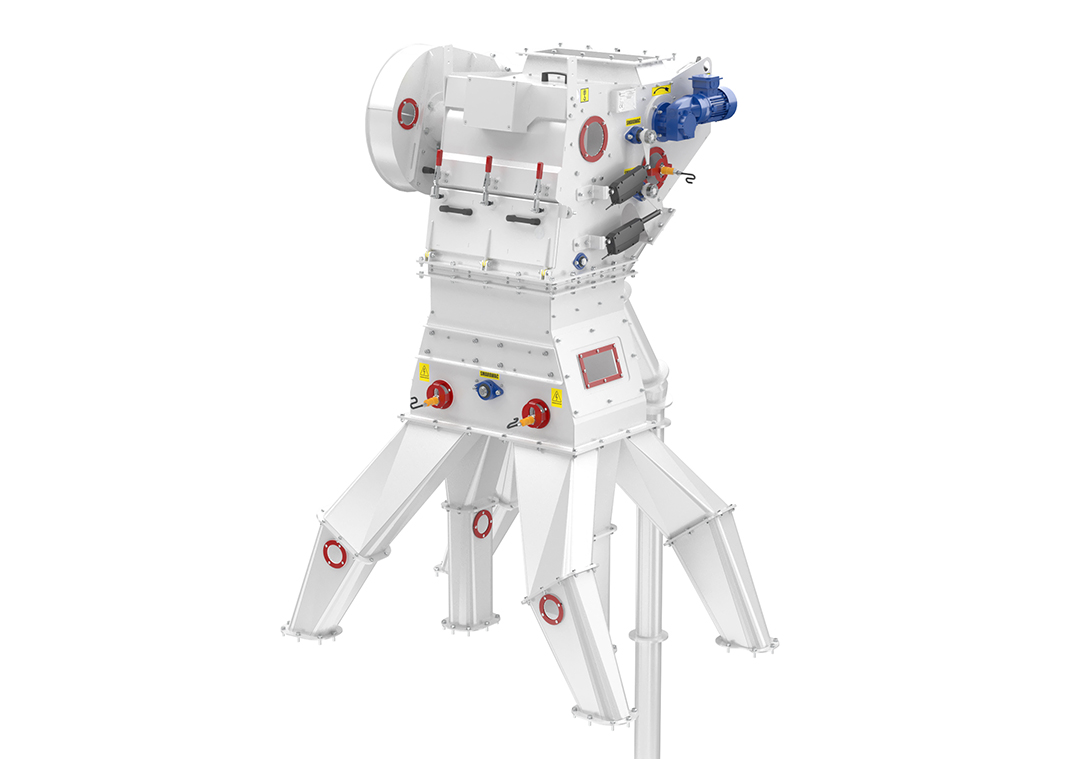

A vertical hammer mill is used to grind such components as grains, pulses and oilseeds.

A vertical hammer mill is used to grind such components as grains, pulses and oilseeds. The device is intended for the agri-food industry, where there is a necessity to grind the raw material before it is subjected to further processing.

It is manufactured in two sizes:

- MBE001 – capacity of 8-18t/h, power: 75kW (63/73kW in a two-speed model)

- MBE002 – capacity of 15-34t/h, power: 132kW

Advantages of the device

- energy savings when compared to equivalents

- low heating of the product during the grinding process and low moisture losses

- controlled, identical size particles with a high variability range

- consistent grinding performance

- easy and fast replacement of sieves and beaters

- low operational cost.

Our offer includes two models of mills, which slightly differ in terms of structural elements and performance. The mills consist of the following sub-assemblies. Some of the elements of the listed equipment are optional, and some of them are part of a larger mill model:

- support plate with legs

- hopper featuring an electrical system

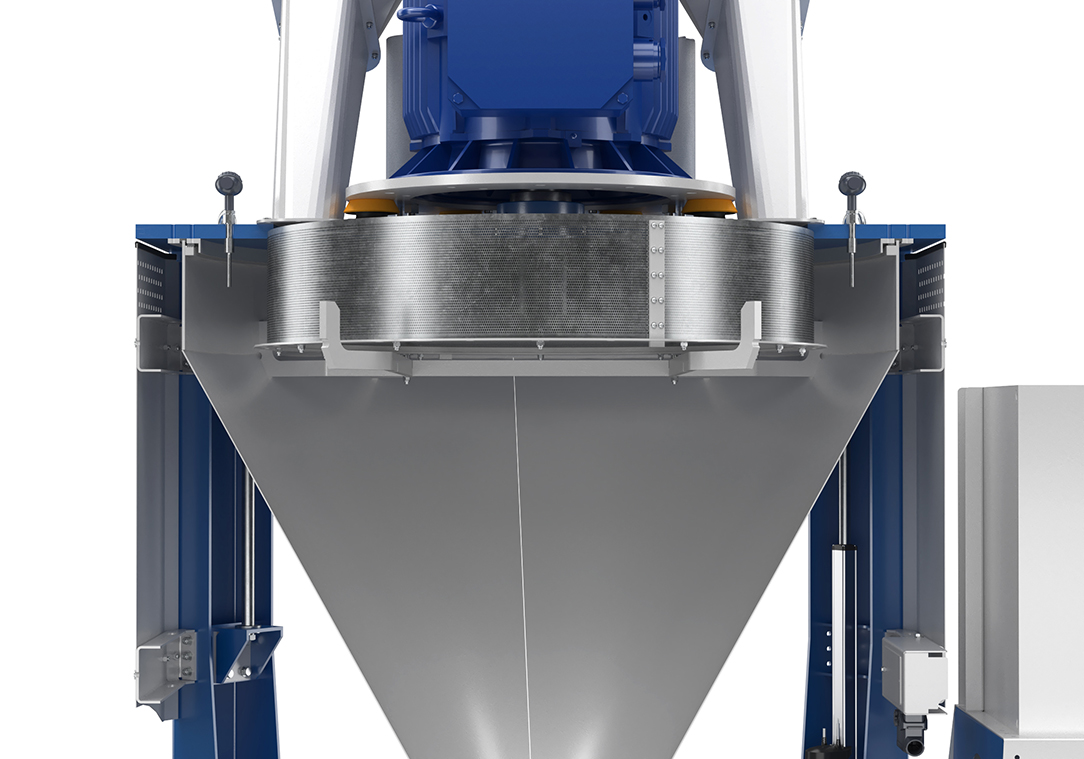

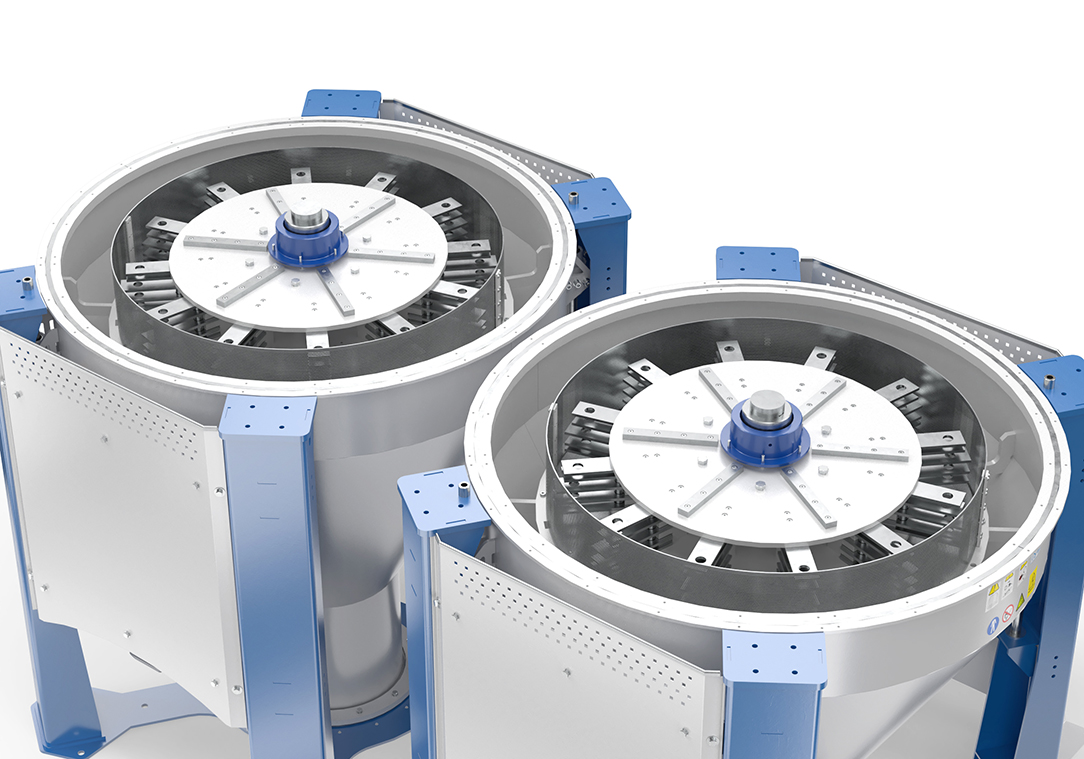

- rotor with beaters (18/60 beaters; rotor with 745/1050mm in diameter)

- sieve

- three-phase motor

- electrical control cabinet (MBS002)

- safety and auxiliary equipment systems

- guards and sensors.

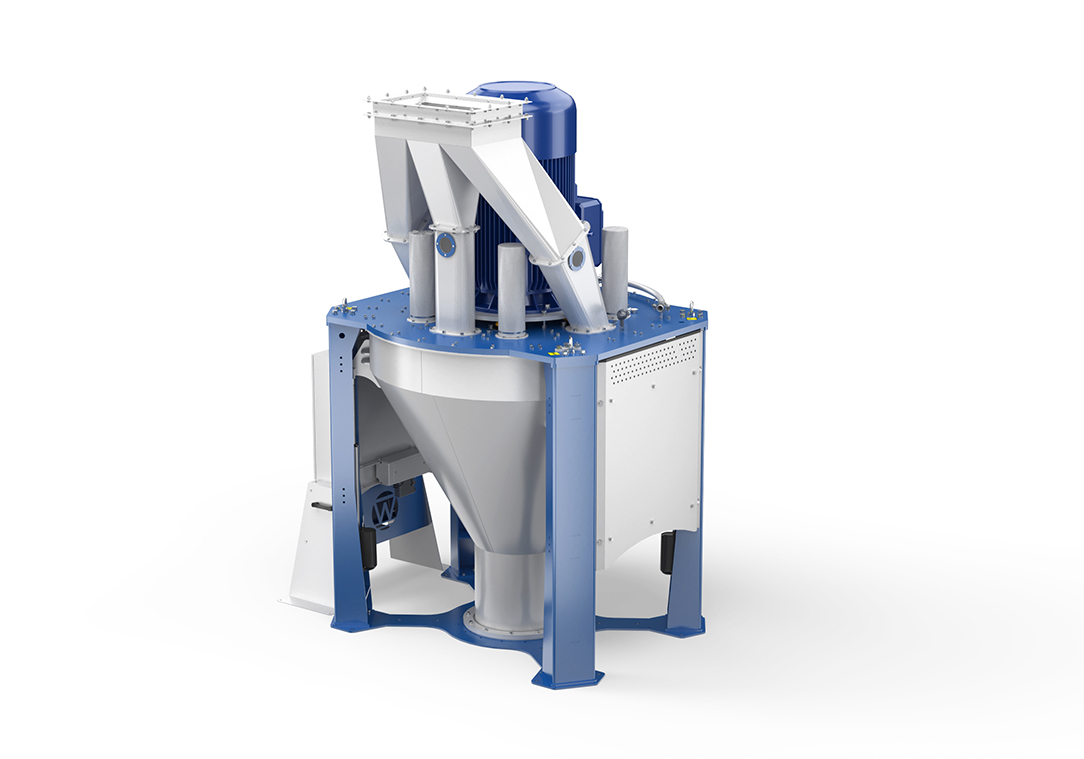

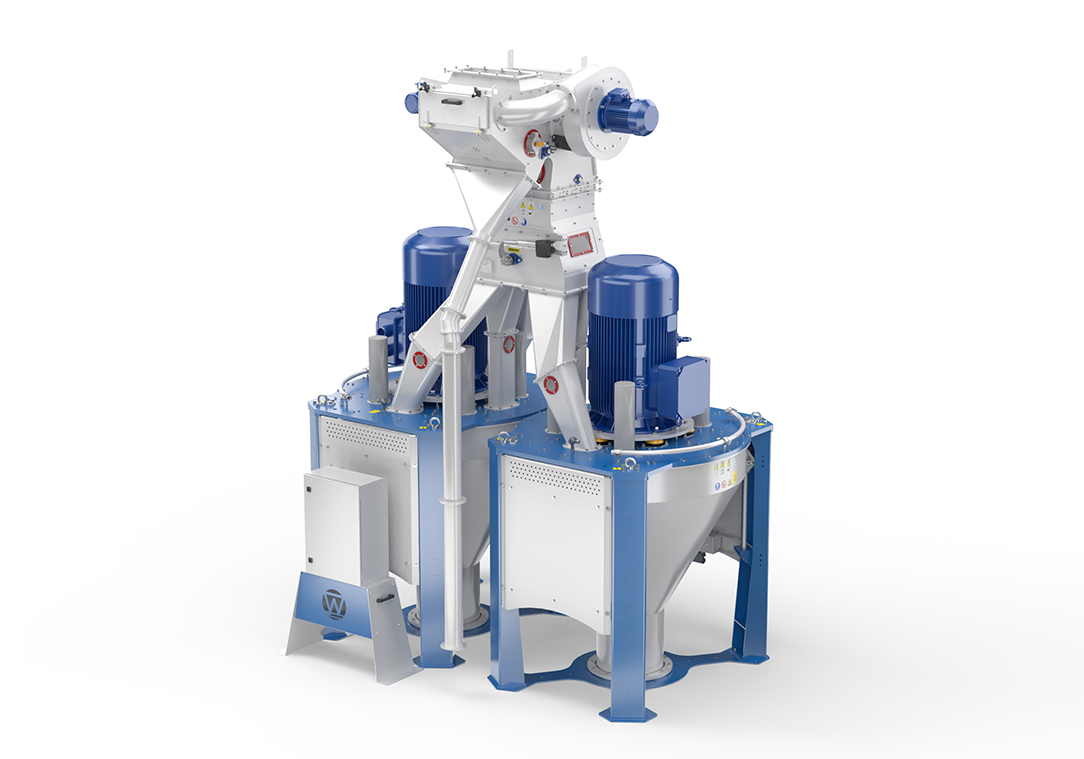

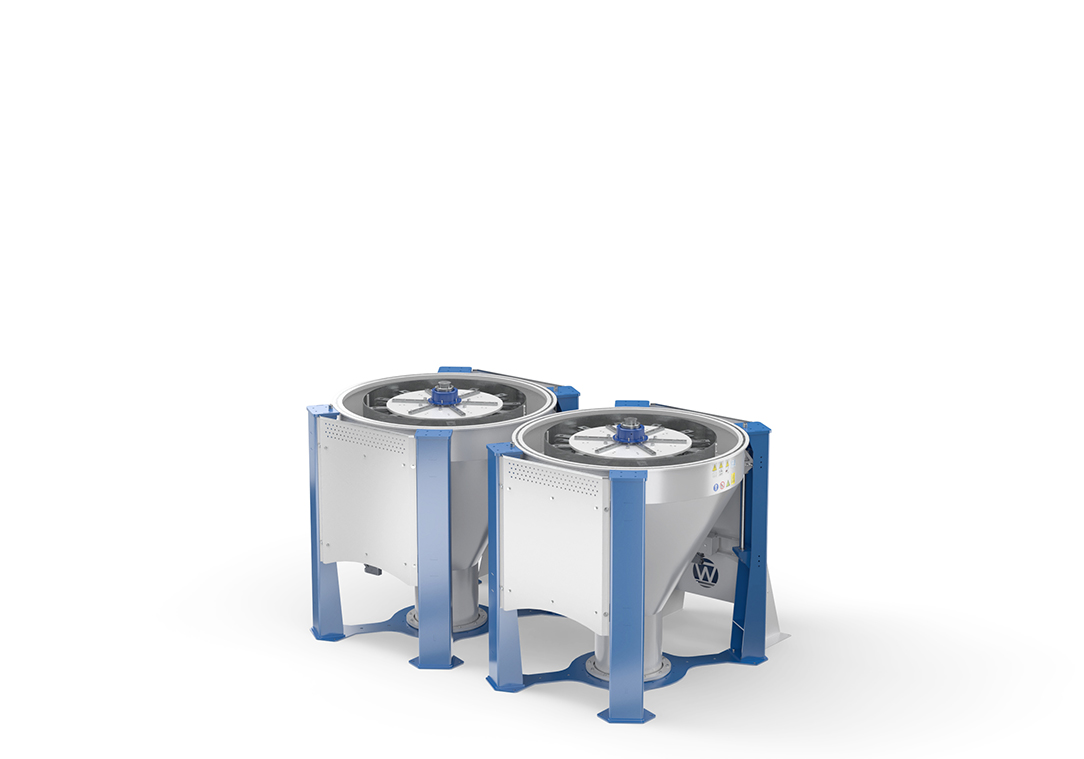

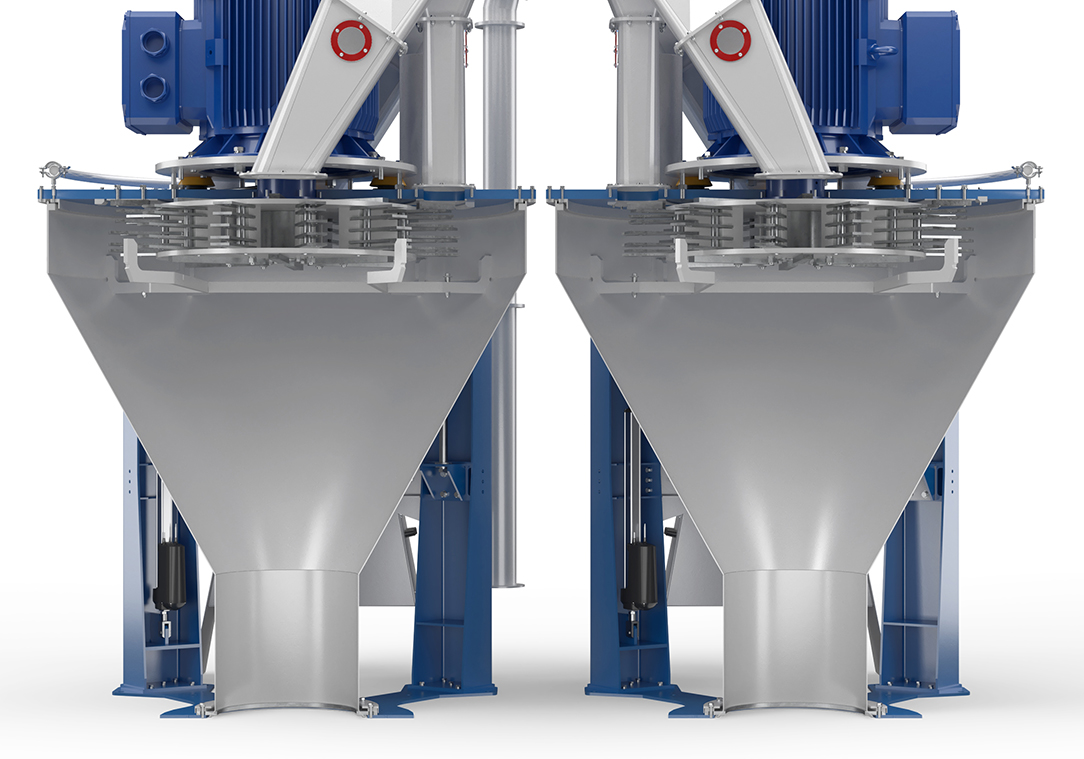

In order to increase the performance of the line, it is possible to use a double system (so-called tandem), which consists of:

- dosing device which doses raw materials into a system which consists of two mills, and then separates the ferromagnetic pollutants and others (stones); it is installed in a system with two mills and valve boxes

- valve box

- hopper

- two identical mills.

Vertical hammer mill

Vertical hammer mill

Vertical hammer mill

Vertical hammer mill

Vertical hammer mill

Vertical hammer mill

Vertical hammer mill

Vertical hammer mill

Vertical hammer mill

Vertical hammer mill

Vertical hammer mill

Vertical hammer mill

Vertical hammer mill

Vertical hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill

Vertical tandem hammer mill