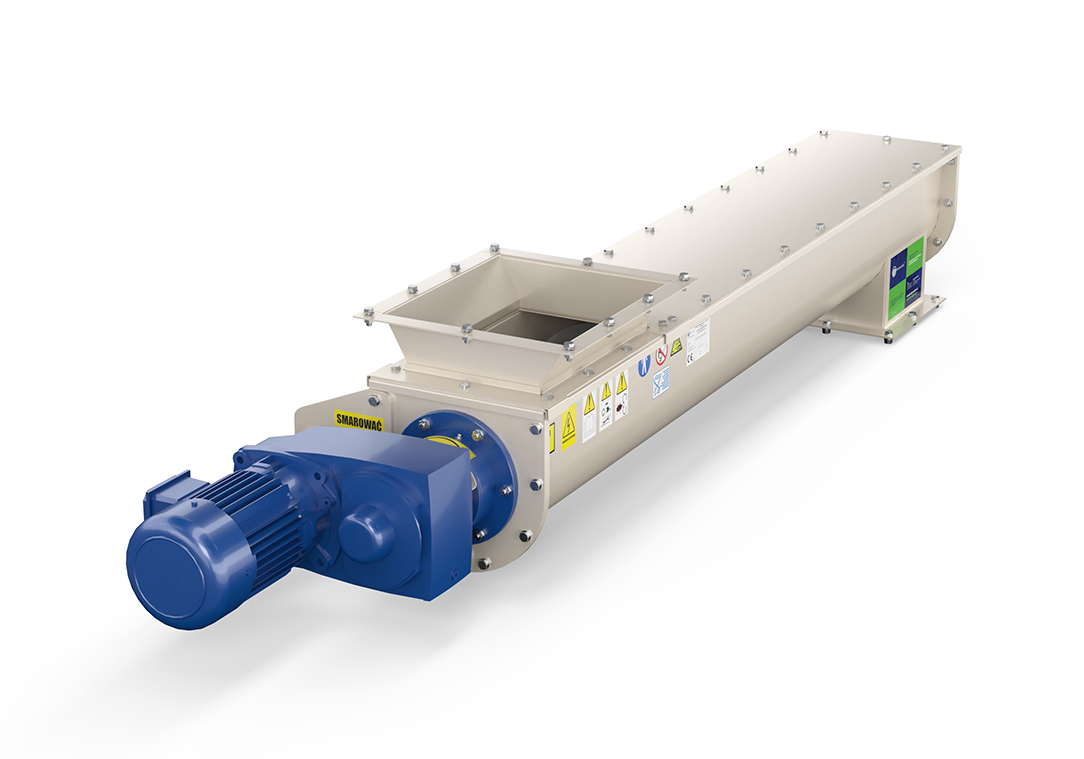

Screw conveyor

A screw conveyor is a device that is used both in agriculture and industry.

A screw conveyor is a device that is used both in agriculture and industry. It is intended for horizontal and diagonal transport of loose materials such as grains, bran, pulses and oilseeds, salts, phosphates, chalk, sawdust, biomass and pellets.

Because of its specifics and high vulnerability to modifications (including inlets and outlets as well as strokes and lengths of the auger), it may fulfil different functions in process lines: from operation as a typical conveyor, through to the function of a feeder, to the operation as a dispenser in weighing systems and technological processes. It can operate in the pushing and pulling version.

The maximum capacity of a screw conveyor, depends on the type of material transported, the geared motor revolutions and the angle of inclination.

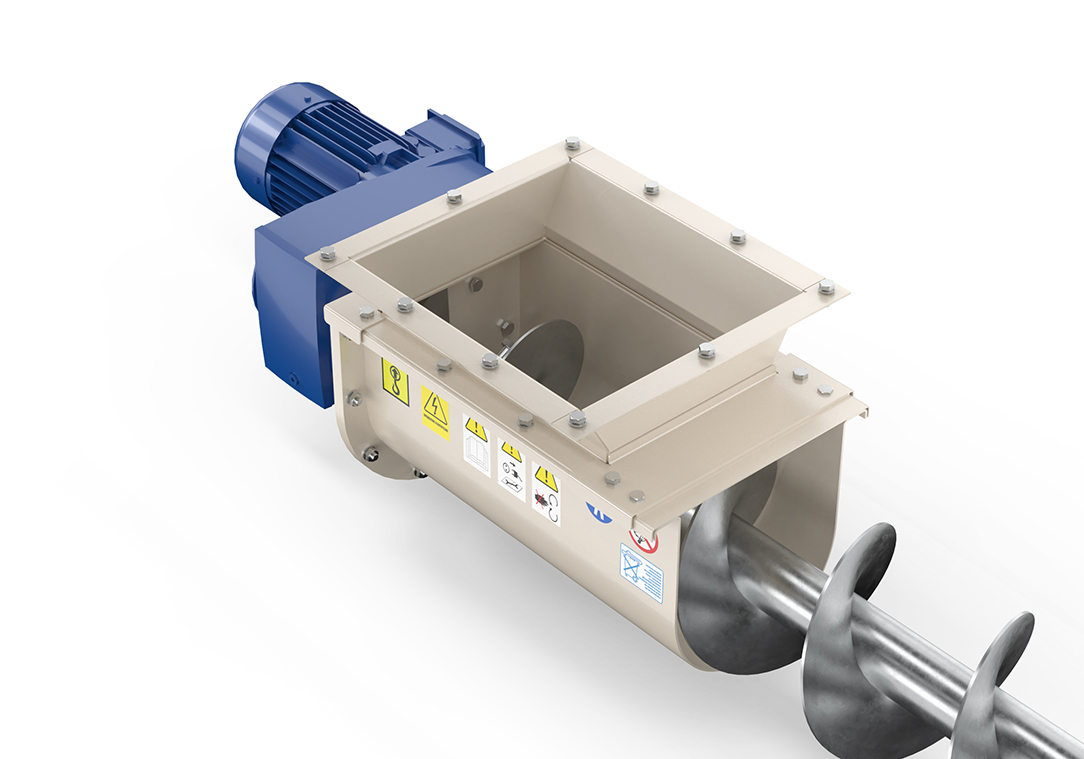

The screw conveyor is made in two versions:

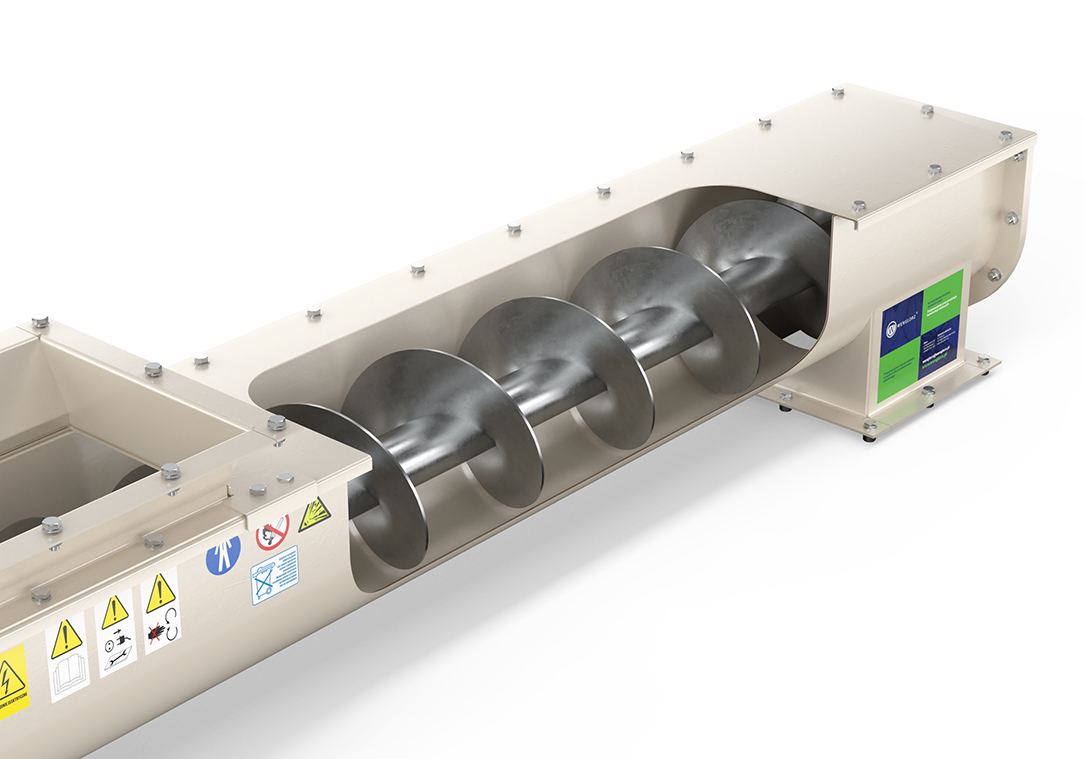

- trough conveyor – with the U-shaped casing provided with covers that can be unscrewed. It is mainly used in areas where frequent cleaning is necessary or where there is a risk of blocking the operation of the conveyor by large elements that act as a wedge between the casing and the auger.

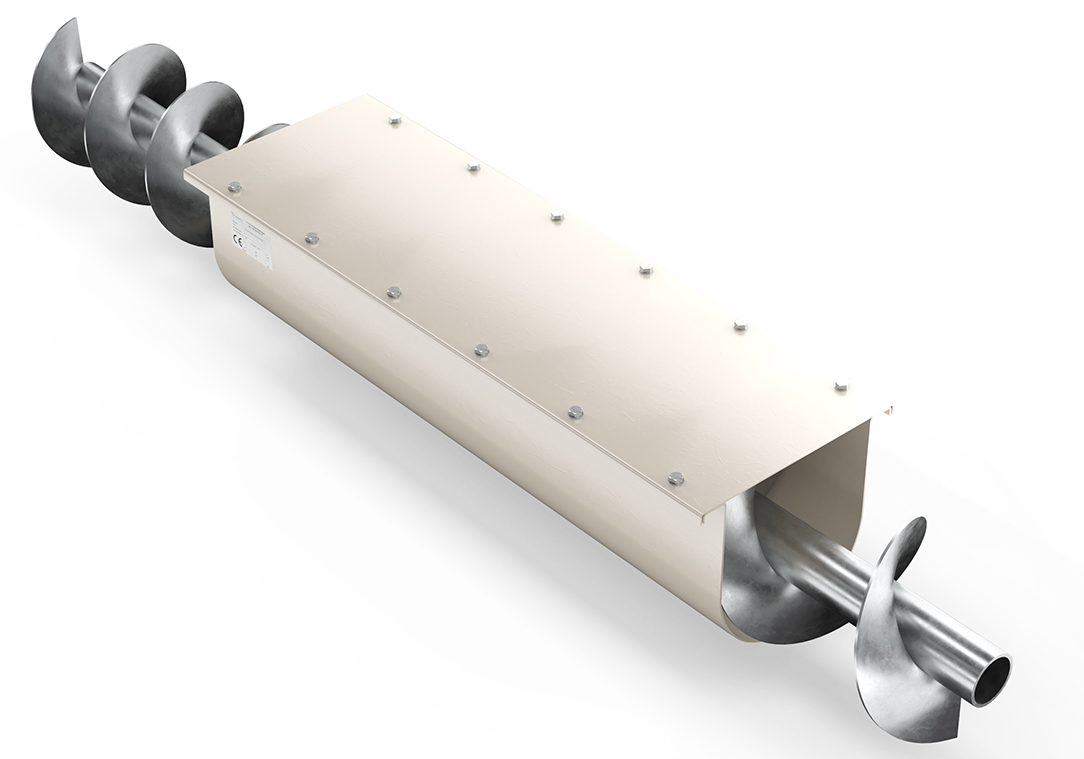

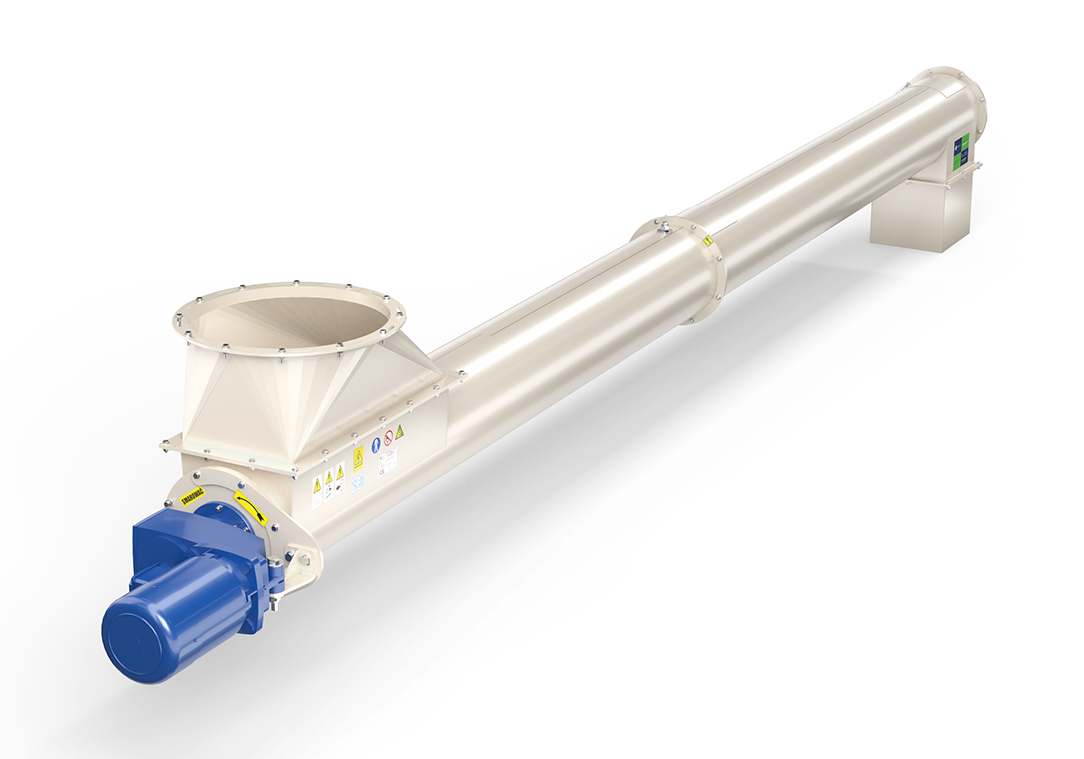

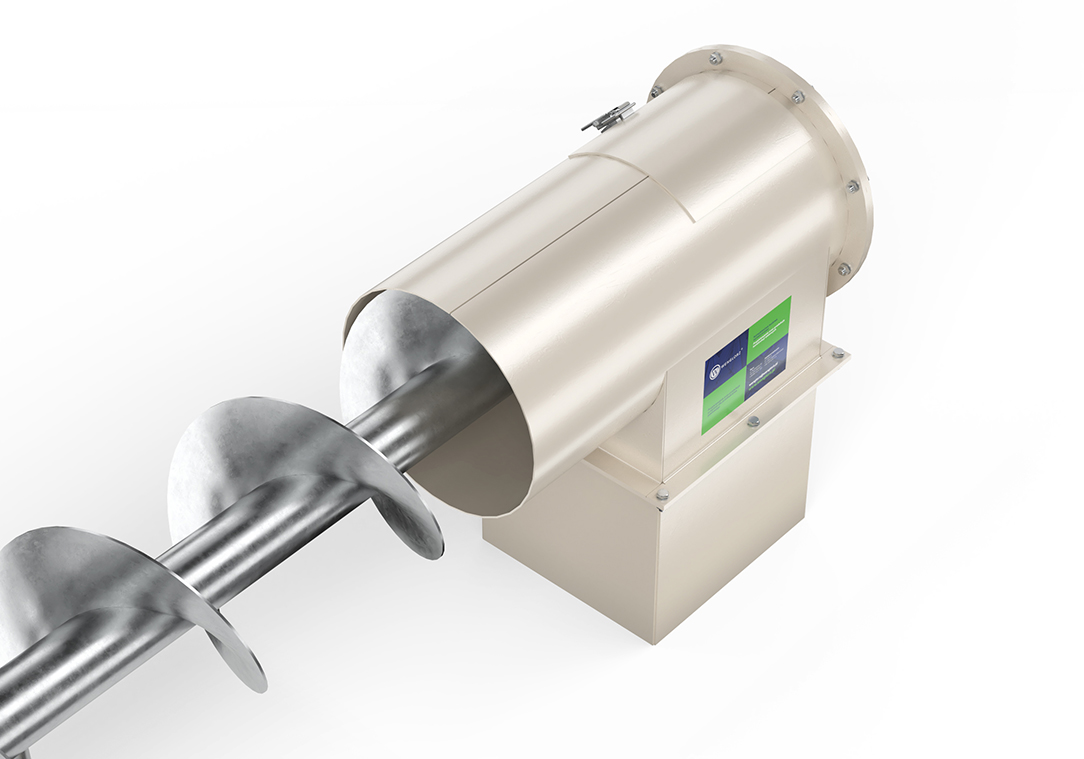

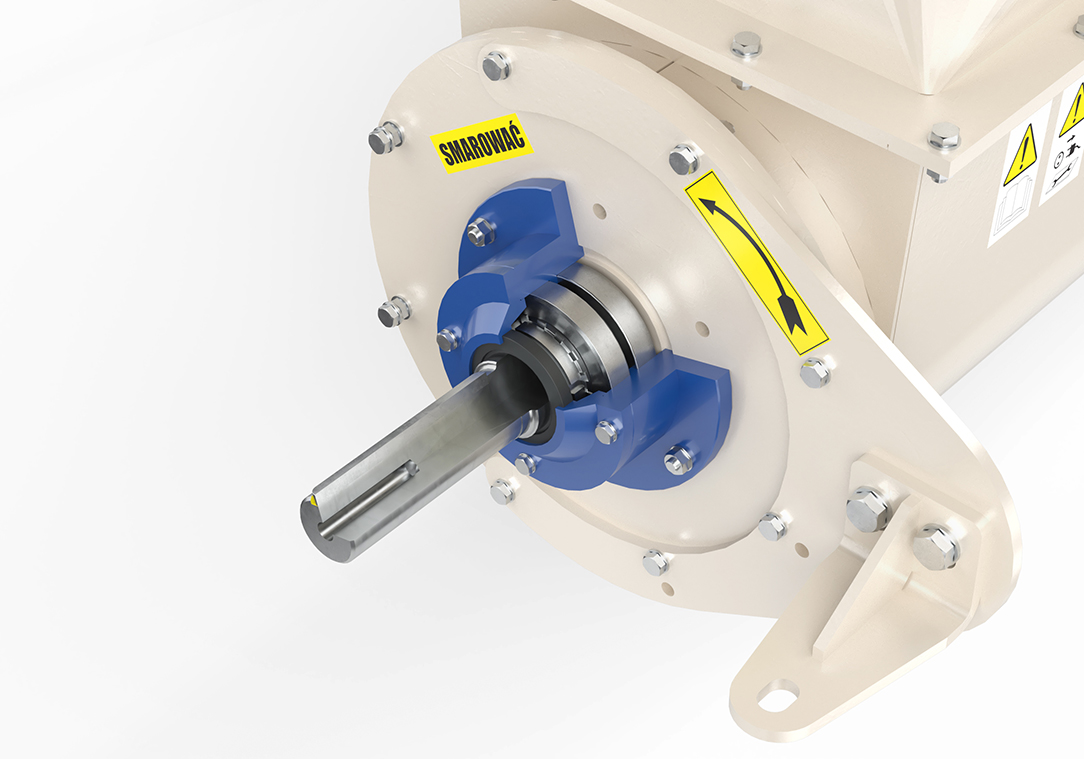

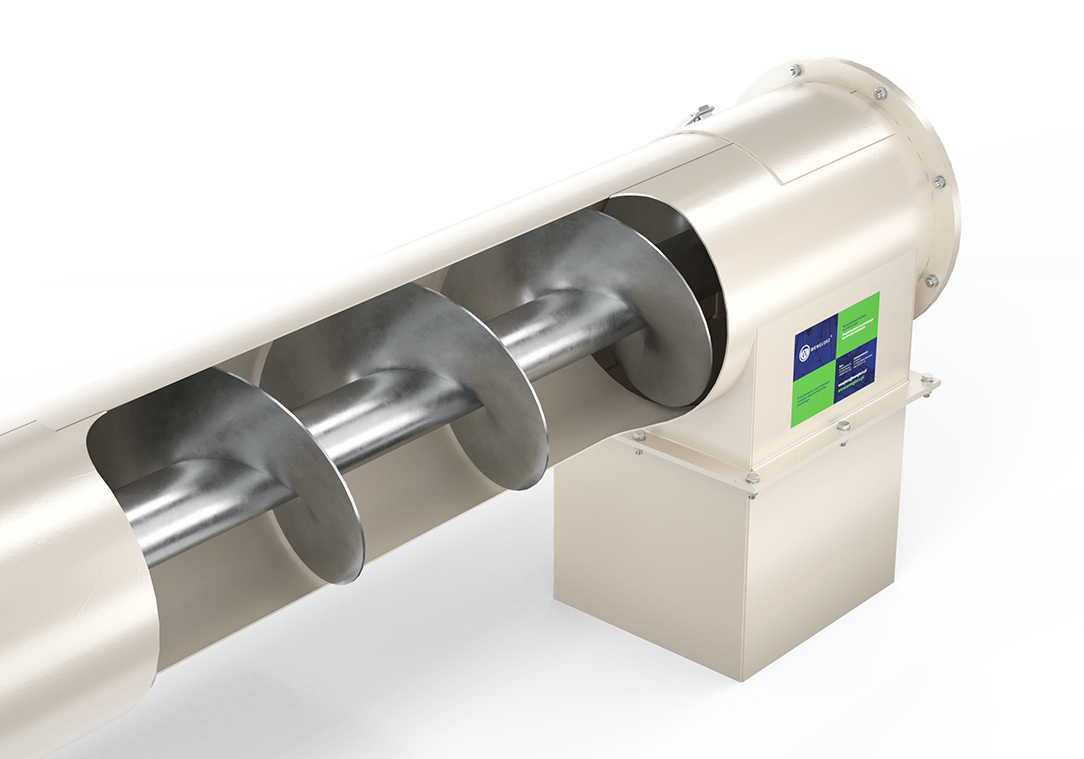

- tubular conveyor – the casing is made in the form of a tube, inside which a wormwheel rotates. Because of its design, the device is more leak-tight and may operate as a separator of process line zones.

Conveyors are typically painted in RAL 1015. Optionally, it is possible to use other colours. At the Client’s request, the devices may be carried out in stainless steel and galvanised versions.

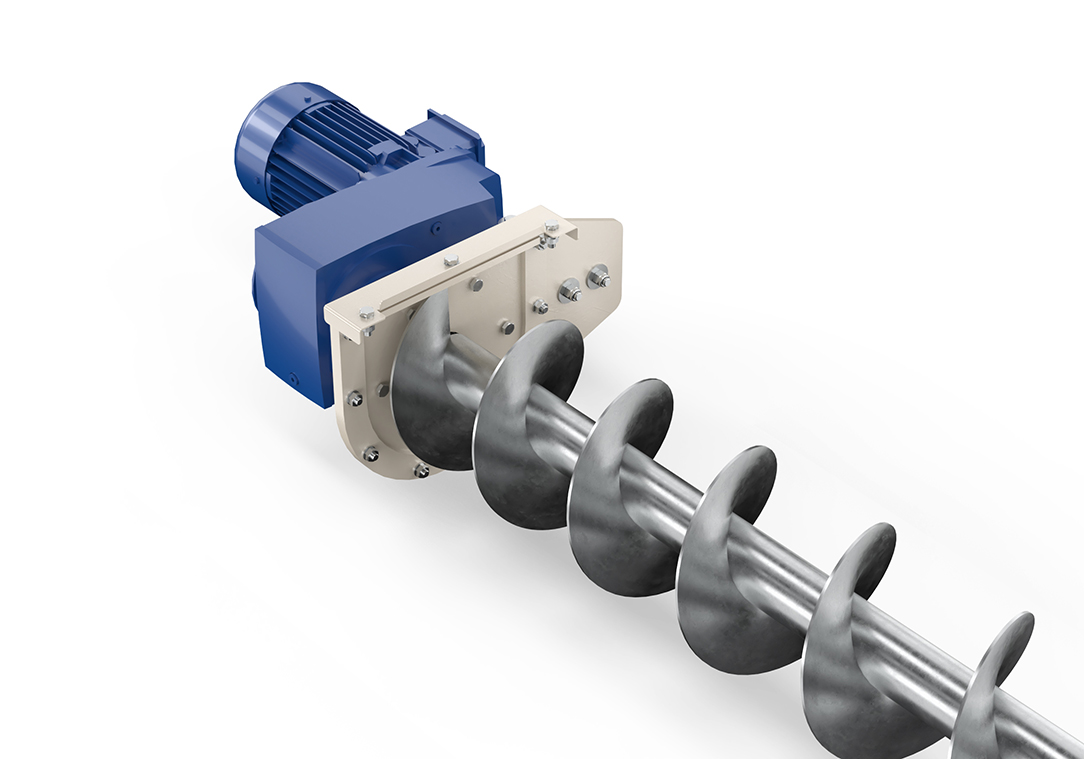

Design

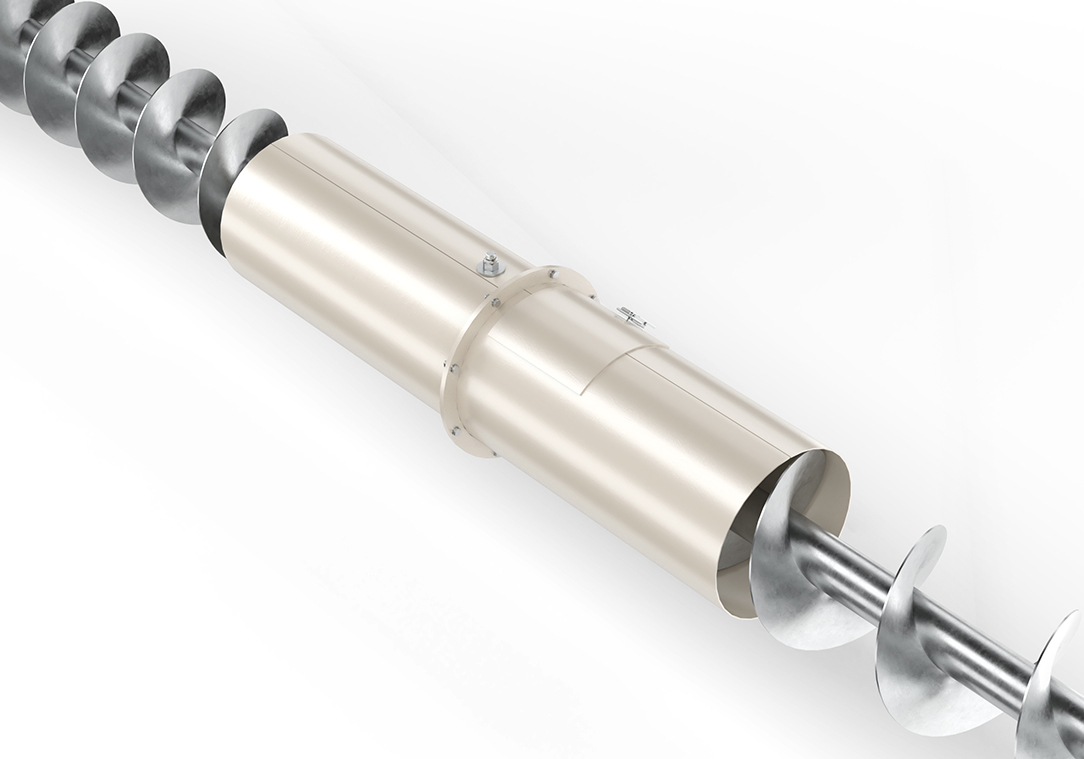

- initial, central and end segment

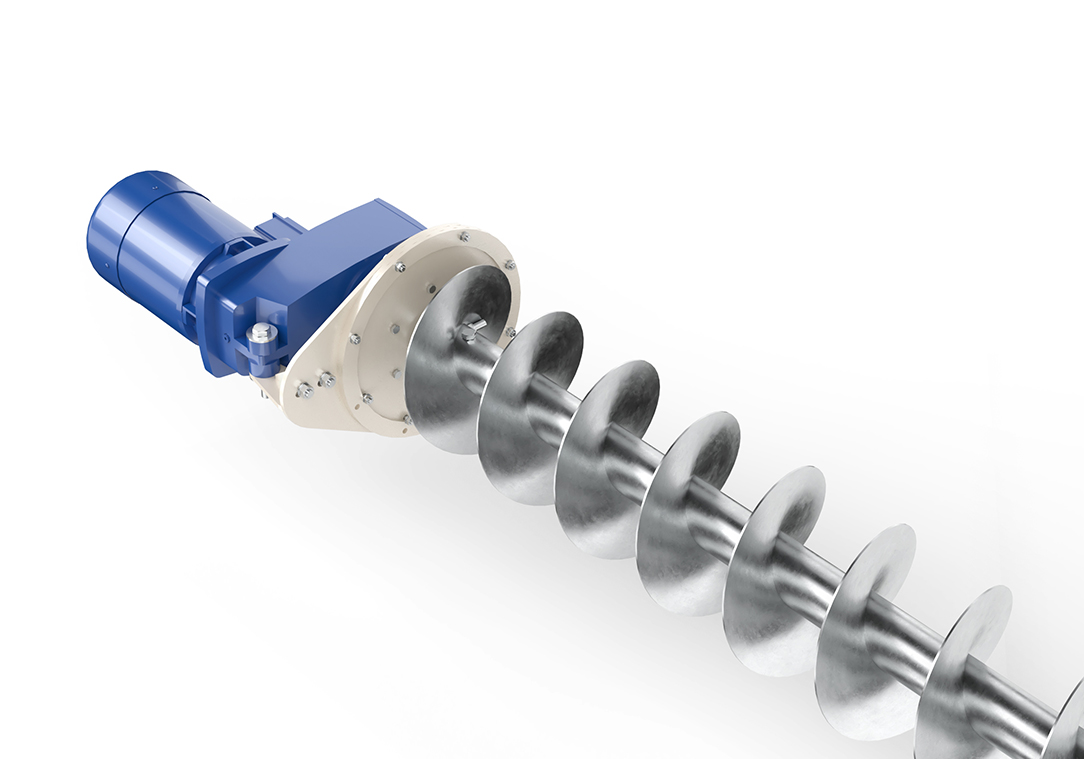

- wormwheel

- drive

Trough screw conveyor

Trough screw conveyor

Trough screw conveyor

Trough screw conveyor

Trough screw conveyor

Trough screw conveyor

Trough screw conveyor

Trough screw conveyor

Trough screw conveyor

Trough screw conveyor

Trough screw conveyor

Trough screw conveyor

Trough screw conveyor

Trough screw conveyor

Tubular screw conveyor

Tubular screw conveyor

Tubular screw conveyor

Tubular screw conveyor

Tubular screw conveyor

Tubular screw conveyor

Tubular screw conveyor

Tubular screw conveyor

Tubular screw conveyor

Tubular screw conveyor

Tubular screw conveyor

Tubular screw conveyor

Tubular screw conveyor

Tubular screw conveyor