Production

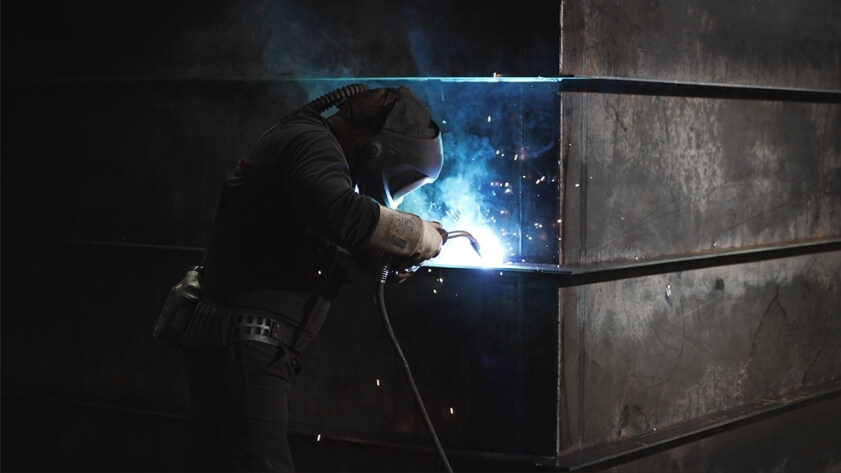

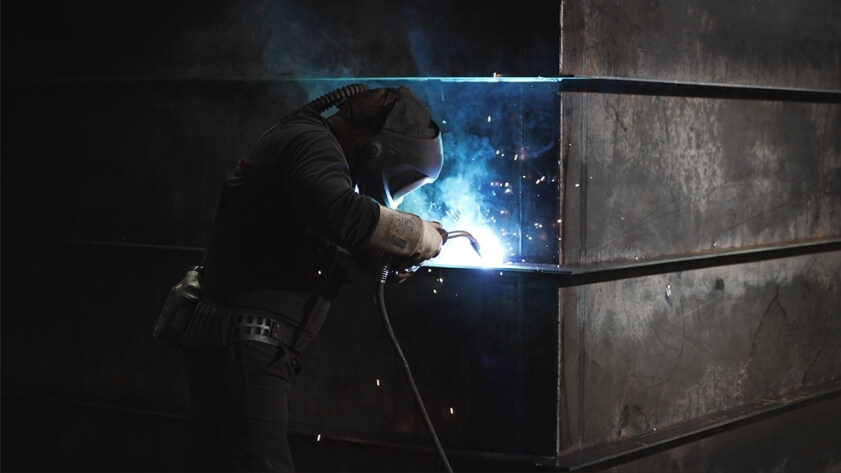

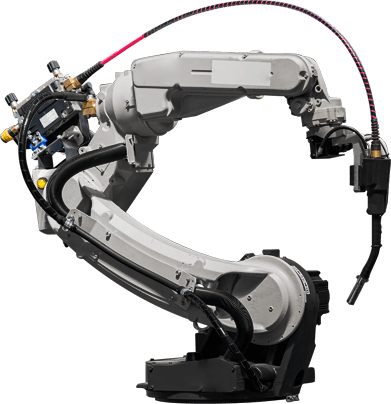

Our leading position on the Polish market and full indpendence would never have been achieved without our own production plant. This is where the solutions designed by the #Wenglorz Expert engineering team are transformed into top quality finished products.

Produkcja Maszyn Rolniczych, Urządzeń Przemysłowych i Linii Technologicznych

This is possible owing to our modern machinery park, experienced and competent staff and certificates which confirm the quality of the work which we perform.

The process and conveying equipment, steel structures and other elements of technological lines which are widely recognised and appreciated by the leading players of the agro-food market are manufactured on an area of over 35,000 m2.

In connection with the necessity of using harmful and hazardous substances in the technological processes, we place great emphasis on the protection of employees and the working environment from their adverse effects, in accordance with the applicable legal requirements.

OUR PRODUCTS

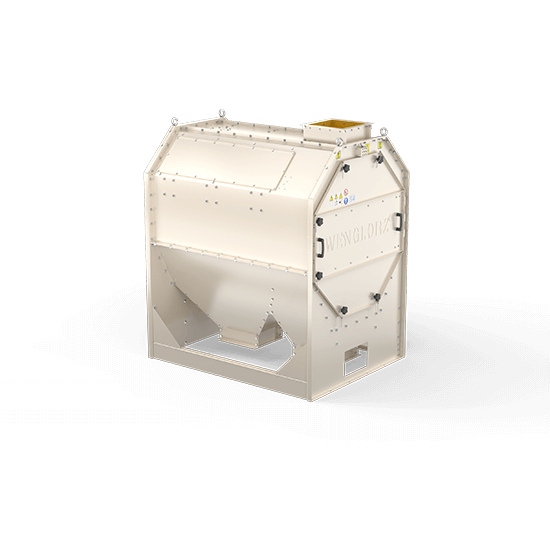

A drum screener is used for the preliminary sifting of the material intended for production, coarse pollutants such as stones, pieces of plants, strings or wire, etc.

The rotary screener is used to separate lumps, fine fractions from pellet, etc. in such a way as to prevent undesirable fractions, especially dust, from entering into the final product.

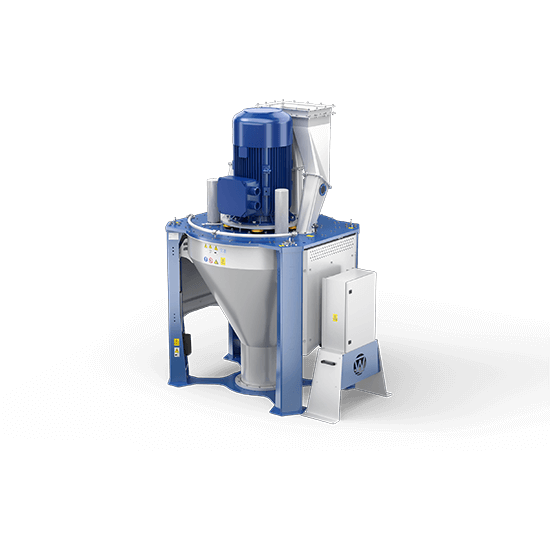

A vertical hammer mill is used to grind such components as grains, pulses and oilseeds.

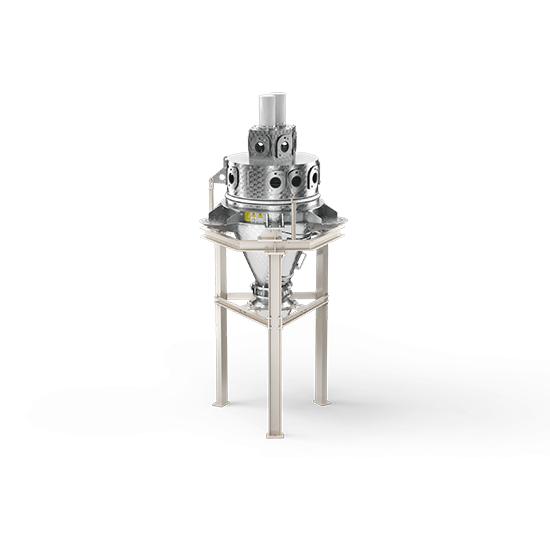

Tensometric macro scales are designed for weighing loose macro-components.

Tensometric micro scales are designed for weighing loose micro-ingredients.

A micro-weighing station is also referred to as the micro-material dosing section.

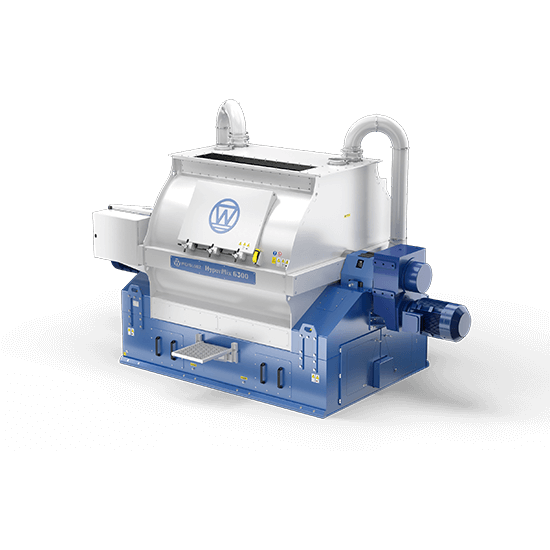

The horizontal paddle mixer (HYPERMIX) is intended for the fast and efficient mixing of portions of powder ingredients including: complete feeds, concentrates and feed premixes.

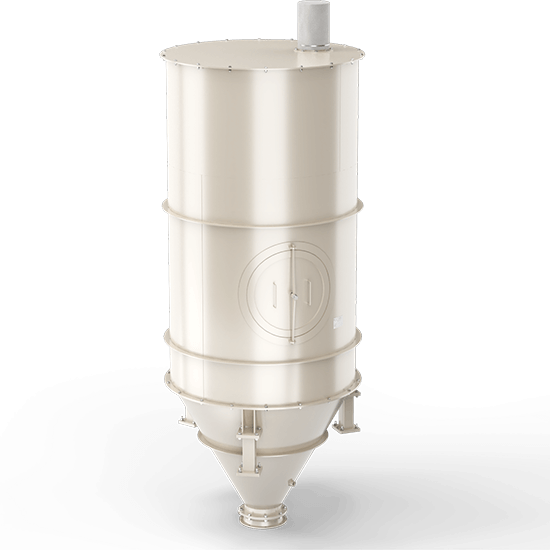

Wydajne i bezpieczne przechowywanie pasz to kluczowy element w funkcjonowaniu każdego gospodarstwa rolnego. Dobrze zaprojektowany silos paszowy pozwala na zachowanie wysokiej jakości surowca, ochronę przed wilgocią oraz minimalizację strat materiału. Wenglorz oferuje wysokiej jakości silosy paszowe. Producent ma ponad 30-letnie doświadczenie, przez co wszystkie konstrukcje dopasowane do indywidualnych potrzeb klientów z branży rolniczej i przemysłowej. Nasze rozwiązania wyróżniają się solidnym wykonaniem, nowoczesnym designem oraz pełną zgodnością z normami bezpieczeństwa.

Silos zbożowy to kluczowy element infrastruktury w każdym gospodarstwie rolnym oraz przedsiębiorstwie zajmującym się magazynowaniem i przetwarzaniem zbóż. Firma Wenglorz od lat projektuje i produkuje niezawodne konstrukcje, które zapewniają bezpieczne przechowywanie ziarna, chroniąc je przed wilgocią, szkodnikami i utratą jakości. Oferowane przez nas rozwiązania są dostosowane do potrzeb zarówno dużych zakładów przetwórstwa rolnego, jak i mniejszych gospodarstw, stanowiąc integralną część kompleksowego systemu.

Zbiorniki ze stali nierdzewnej z naszej oferty to gwarancja niezawodności i jakości. Produkujemy i montujemy kompleksowe linie technologiczne, które znajdują zastosowanie w przemyśle rolno-spożywczym. Zbiorniki nierdzewne charakteryzują się wysoką odpornością na korozję oraz długą żywotnością, co czyni je niezbędnym elementem w każdej nowoczesnej produkcji. Oferujemy również indywidualne projekty dostosowane do specyficznych potrzeb Twojej działalności. Poznaj zalety naszych rozwiązań i przekonaj się, jak mogą one wpłynąć na optymalizację Twoich procesów produkcyjnych.

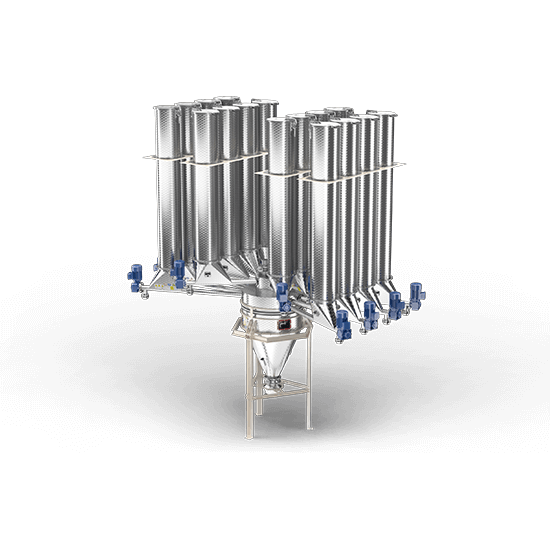

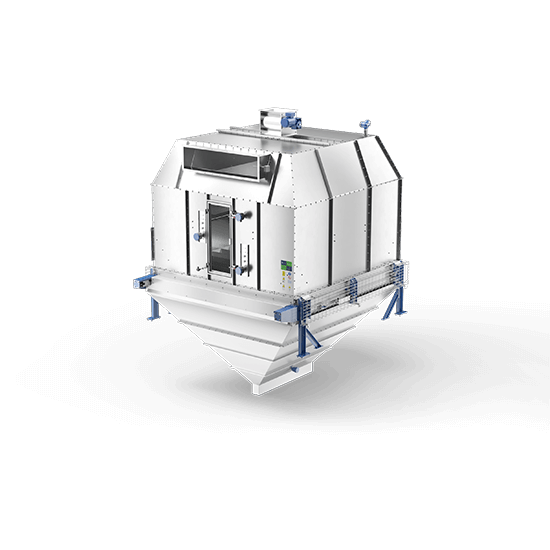

Process (operating) bins are part of the technological equipment of compound feed plants, grain silos and other agri-food industry facilities.

The cooler is designed to cool down pellets from a temperature of about 80°C to a temperature of about 8°C above the ambient temperature.